Tournaire’s Packaging Division designs, manufactures and sells barrier packaging. It supplies a wide range of industrial sectors: human and animal health, crop protection, fragrances, well-being, food products and dietary supplements, and also specialty chemicals, electronics and laboratory supplies, offering the highest levels of quality, service and safety.

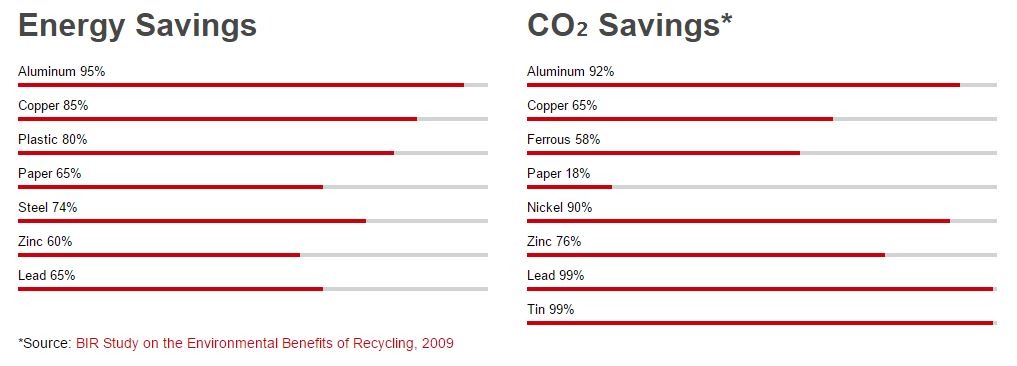

Tournaire’s Packaging Division thus proposes numerous types of aluminum or co-extruded plastic packs with their closing systems, offering users the best possible guarantees and enabling them to transport sensitive or fragile products all over the world in complete security.

Whatever your needs and depending on your special circumstances, the Research and Development department of Tournaire’s Packaging Division can find THE right answer: custom made solutions, creation of new products and special services … all accompanied by a range of customized services.

Tournaire’s range of aluminum packaging is both the broadest and deepest on the market: the “broadest” with more than a score of families of technical packaging: the “deepest” with the greatest range of sizes, from the smallest 15 ml packs to the largest at 60 liters.

Whether in indefinitely-recyclable aluminum, in HDPE plastic or co-extruded; Tournaire’s packaging complies with the strictest regulatory standards applicable in the industrial sectors concerned.

Tournaire is therefore THE trusted partner for thousands of industrial clients in France and more than 70 other countries worldwide.

Tournaire: produces the best, protects the most!