Overlooking the French Riviera from foothills resplendent in the colours of Tuscany, between the sea and the mountains, the town of Grasse has prospered since the early Middle Ages.

Grasse, doing brisk business in a traditional industry: tanning

It became a powerful, independent city in the 12th century, controlling access to the entire hinterland and doing brisk trade with Italy. In the early 15th century, the tanning industry developed considerably, for which the town was reputed all over Europe. Grasse leather was famous for its quality and green hue obtained by macerating it in myrtle. Further to the unification of Provence with the French kingdom in 1482, Grasse was able to expand its flourishing tanning business (gloves bags and belts) even further afield. The magnificent fortified city also started large-scale production of jasmine, the May rose, tuberose and lavender in 1560,.

The downside to tanned leather was its unpleasant smell. To better cater to the requirements of the aristocracy, a tanner from Grasse hit on the idea of adding perfume to his leather gloves. He is said to have offered a pair to Catherine de’ Medici, who loved them so much, she launched a new fashion for perfumed gloves at the French court, thus sparking Grasse’s global reputation. In 1614, Louis XIII created the glove and perfume makers guild, which developed such delights as marzipan gloves “à la provençale”.

The birth of the perfume industry

Hit by heavy taxation and competition from across the Alps in Italy, the tanning industry then suffered gentle decline through to the late 18th century. However, this coincided with the wearing of perfume being increasingly included in beauty routines. While the two lines of business were intertwined, perfume started to boom. With perfume makers growing many different aromatic plants and flowers in the Grasse country’s unique climate and soil, the perfume business ousted tanning in Grasse, soon to flourish and carve out the city’s reputation worldwide.

In the 19th century, the perfume business scaled up from craftsmanship to industry. Large family businesses started up, some of which are global leaders today.

Founding of Tournaire to serve Perfume makers

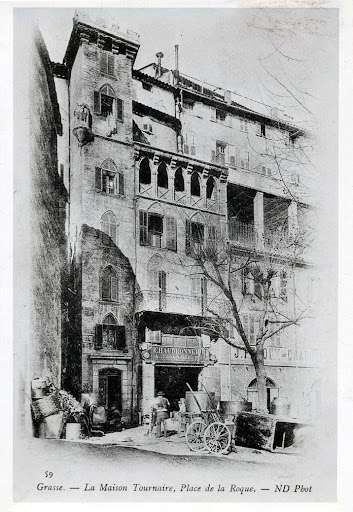

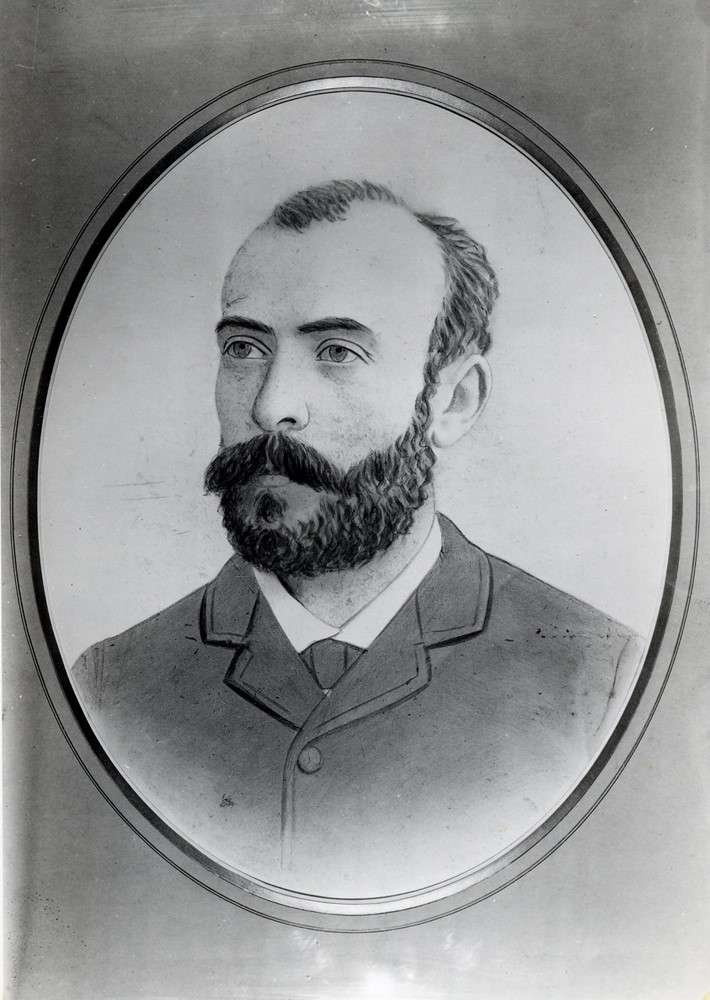

The craftsman’s workshop founded in 1833 on Place de la Roque in Grasse by Joseph Tournaire, also came about thanks to those glove-makers who started selling perfume.

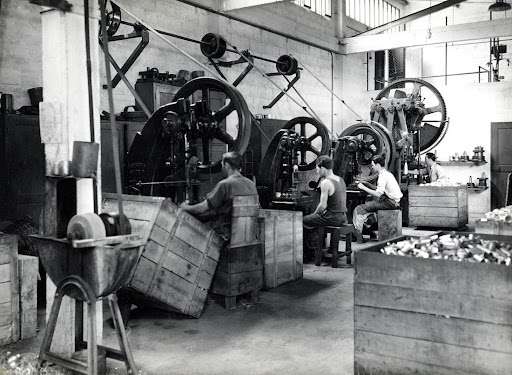

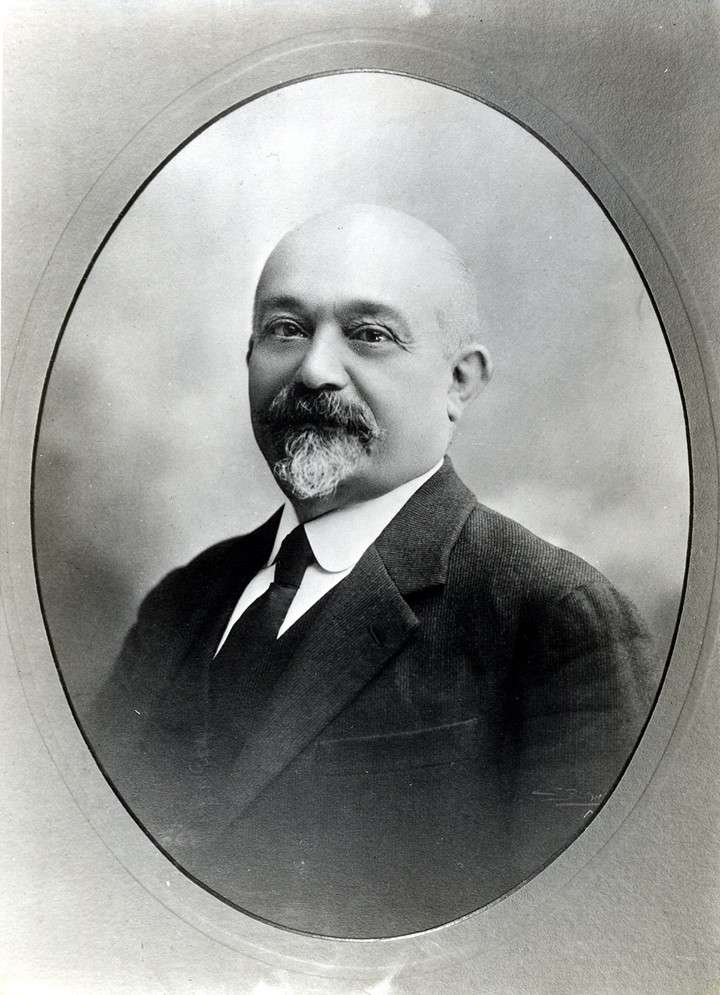

As this industry was taking off, the need to distil natural products developed, ushering in the arrival of the first boilermakers, specialising like Tournaire in the manufacture of stills. With the introduction of steam in manufacturing in the early 1900s, large quantities of raw materials could be handled. Gustave Tournaire harnessed this development to upgrade his boilermaking workshop into a factory.

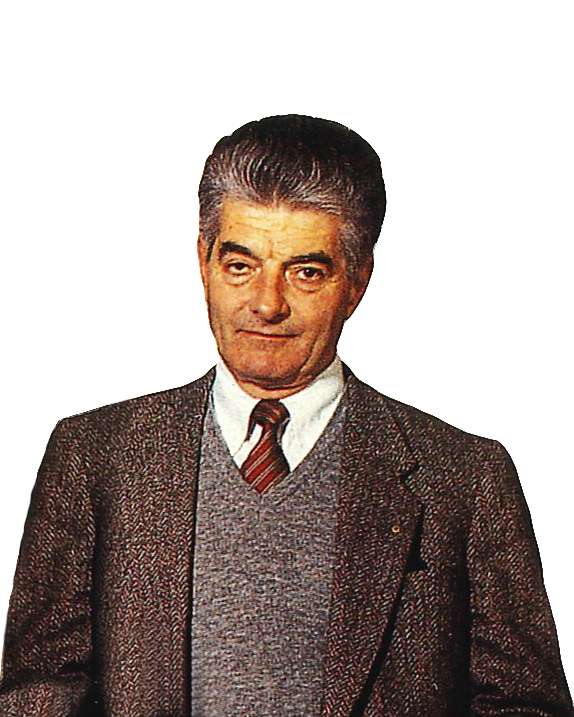

Along with stills, perfume makers also sought sturdy, waterproof packaging to ship their precious essences as far as Australia without any alteration. So Tournaire designed tin-plated copper packaging, including vats in which to ship perfume. Aluminium packaging first took off in the 1930s, driven by Marcel Tournaire, as copper became too expensive, and aluminium processing technology became more effective. Switching from soldered copper to monobloc aluminium, aluminium flasks would be used worldwide.

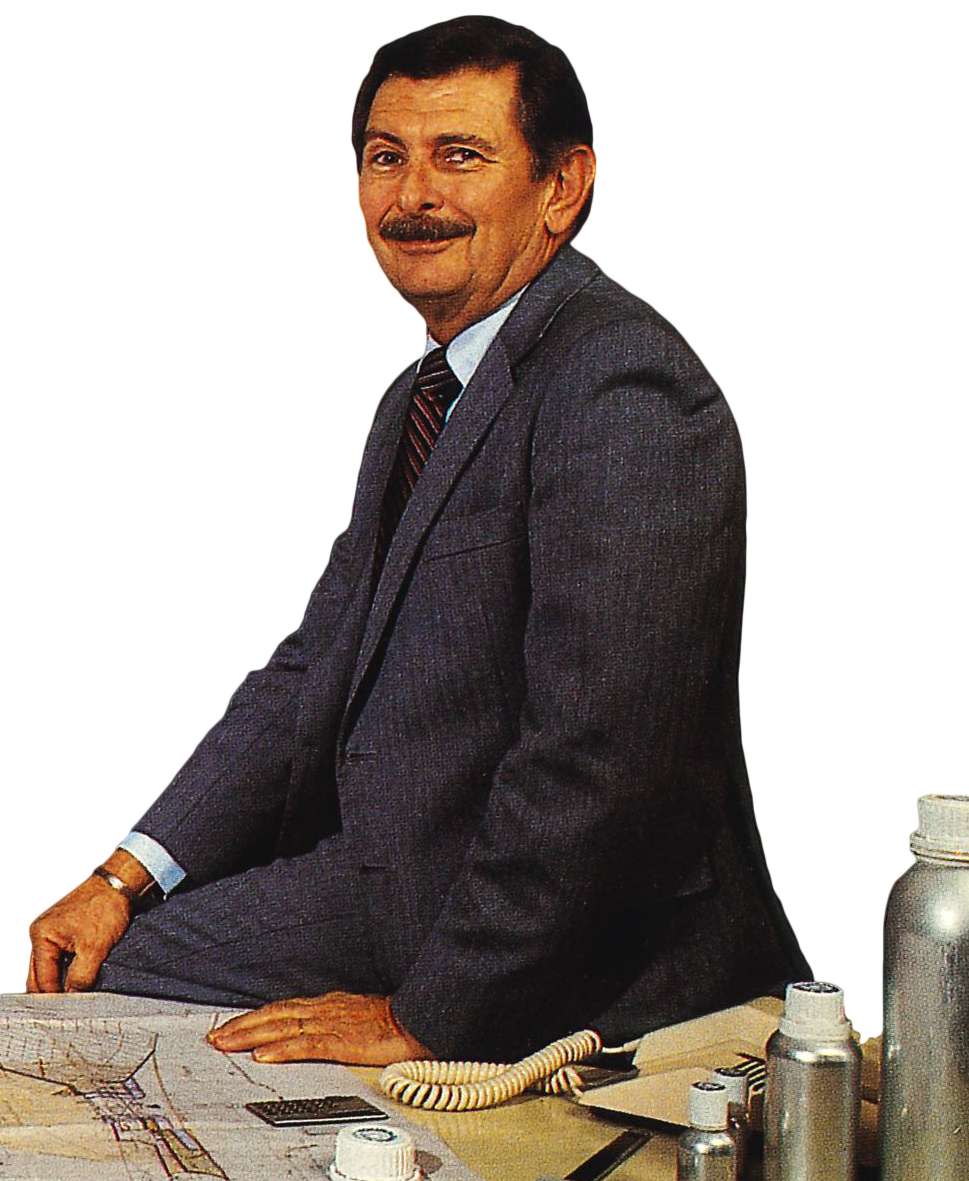

From 1833 to the present, a company standing the test of Time

Emblematic family businesses in the perfume business in Grasse

The perfume business of course included the growing of plants used to make perfume and their processing, and the composition and creation of finished products (perfume and aromas for the perfume business, cosmetics, hygiene and food products). It also drove imports and exports, trade, and the processing of raw materials.

Many family businesses still operate in this industry today, including Mane, founded in 1871, and Robertet founded in 1850, Payan Bertrand founded in 1854, Argeville in 1955 and Jean Niel in 1779.

Like Tournaire, these firms have been directed from the outset by generations of leaders who have managed to preserve their independence, innovating and developing profitably for nearly 200 years now.

According to Philippe Massé, head of the national association of manufacturers of aromatic products (Prodarom) “The Grasse perfume industry boasts 64 firms employing 4,600 staff and a turnover of 2.9 billion euros” (Source Capital – January 2021 – in French only).

“The Grasse basin has played a crucial role in the perfume business, accounting for almost half the perfume business and aromas and something like 7-8 % worldwide”. The family businesses in Grasse have developed a long-lasting heritage, unique in this world. (Source: Wikipedia, in French only).

The war years, the 1929 crash and the boom in international trade have all chipped away at the 20th-century expansion of the industry in Grasse, facing off the spectacular growth of synthetic aromas, propelled by multinational giants based in Switzerland, the US and Germany.

Grasse and nature, consecration and a new boom since 2018

However, the Grasse families have not had their last word.

All players in the Grasse country ecosystem have teamed up with local elected officials to invest heavily in the past years, to promote natural products and a large-scale return to growing perfume plants.

A quarter of Grasse’s territory has been classified as a “protected nature reserve”. Along with other Provence-Alpes-Côte d’Azur and Rhône-Alpes regions, it became a national business cluster in July 2005, boasting its own label called P.A.S.S (Parfums-Arômes-Senteurs-Saveurs).

The association “Fleurs d’Exception du Pays de Grasse” (Amazing flowers in Grasse country) created in 2006 to promote plant production in Grasse country, is an umbrella organisation for 25 perfume plant-growers. Its president, Armelle Janody, confirmed: “Fleurs d’Exception du Pays de Grasse is an association of perfume plant-growers in Grasse country, who have chosen to go organic. They have all signed a charter encouraging solidarity and sharing. The aim of the association is to promote perfume plants and local production”.

In August 2013, the Association Patrimoine Vivant du Pays de Grasse (Living heritage in Grasse country) was created to apply for “the skills related to perfume in Grasse country: the cultivation of perfume plants, the knowledge and processing of natural raw materials, and the art of perfume composition” to be classified as “Intangible Cultural Heritage of Humanity”. Chaired by former French Senator and Mayor of Grasse Jean-Pierre Leleux, this very active association represents all industry players and has gained unanimous approval. It aims to “make a representative List of the Intangible Cultural Heritage of Humanity, including the entire heritage of the Grasse country, encourage its preservation, and promotion, help to raise awareness among the public, by way of publications, websites, meetings, facilitate access to this heritage to as many people as possible by all means, and apply to be listed as Intangible Cultural Heritage of Humanity. Lastly to encourage recognition of Perfume making as an art form”. Click here to find out more.

In 2018, the Grasse country received UN consecration with the listing of its skills related to perfume as Intangible Cultural Heritage of Humanity.

In 2020, elected officials modified the Local Urbanism Plan to multiply possible farmland by more than five, from 178 to 928 ha, i.e. 20% of the town’s territory!, to develop the growing of rose and jasmine.

Major luxury brands placing great importance on the use of natural products are established in Grasse: Chanel, Dior, Lancôme and Louis Vuitton…

From the outset, the Grasse glove and perfume makers used locally available natural raw materials including lavender, orange blossom, rose and mimosa to perfume their gloves.

Synthetic perfumes and aromas by mainly foreign firms had been making inroads for years, yet the entrepreneurs and elected officials in Grasse country have demonstrated a new sense of initiative, and reasserted Grasse as the territory spearheading the revival of natural ingredients in industry, in anticipation of newfound consumer enthusiasm for natural products.

As the birthplace of family businesses in trading and processing of perfume plants and aromas, the composition and the creation of perfume, Grasse country is ever proud of its ranking as the world capital of perfume, quality and natural products worldwide.

Following the success of lavender, orange blossom, rose and mimosa, other plants too are making a comeback: tuberose and jasmine, unique authentic fragrances. All Tournaire staff are proud to help ship these precious, sensitive perfumes the world over.