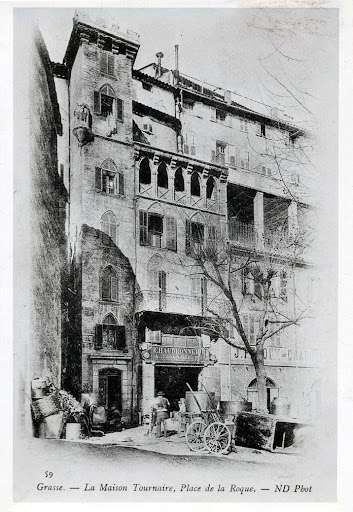

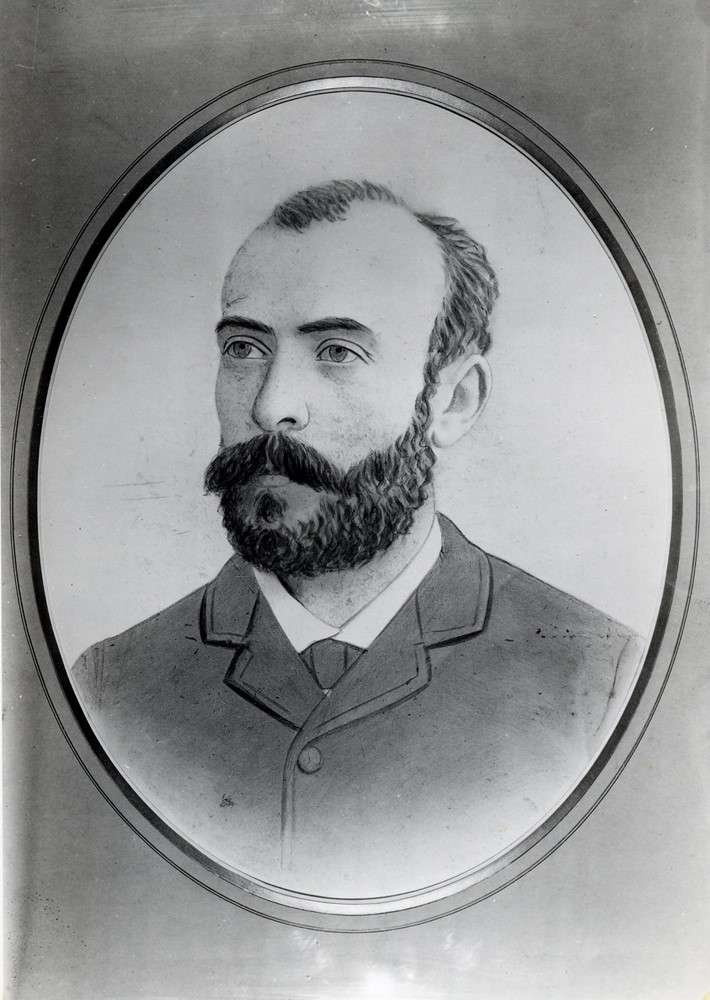

While the busy merchant city of Grasse was already doing brisk business in olive oil, leather and gloves, it still added yet another line of business, that of “perfume oil” and “floral extracts”, leading to a new corporation: that of distillery. This in turn led to the development of boilermakers who were to expand their skills to include the making of stills. And so, in 1833, Joseph Tournaire, son and grandson of millers, set up shop in premises of 40sq.m on Place de la Roque. By the late 19th century, no fewer than six boilermaking workshops catered to the perfume industry in Grasse.

01. 1833 – THE BEGINNING OF AN ADVENTURE

02. 1920 – A FUNDAMENTAL SHIFT

03. 1950 – OPENING TO OVERSEAS

04. 2010 – ROBOTICS FOR QUALITY

05. FAMILY PICTURES

1833 – THE BEGINNING OF AN ADVENTURE

The growth of this industry, the activity of which depended on the season, fostered new needs: reliable storage, without any alteration of sensitive materials and shipping without damaging it. Perfume makers naturally turned to those with expert knowledge in materials and their various properties: the manufacturers of stills.

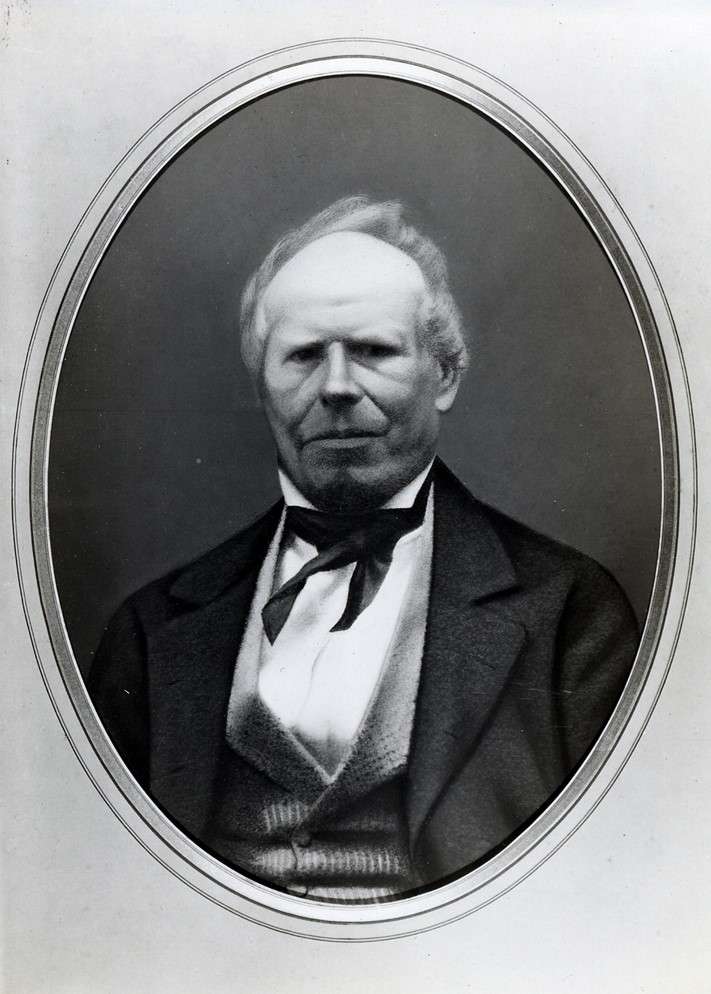

Thus, driven by client demand and based on the success of their stills, for which they received a medal at the 1884 Nice exhibition, the firm Antoine TOURNAIRE Fils soon diversified, expanding into the design and manufacture of tin-plated copper vats. At the time, tin-plated copper was also used for stills.

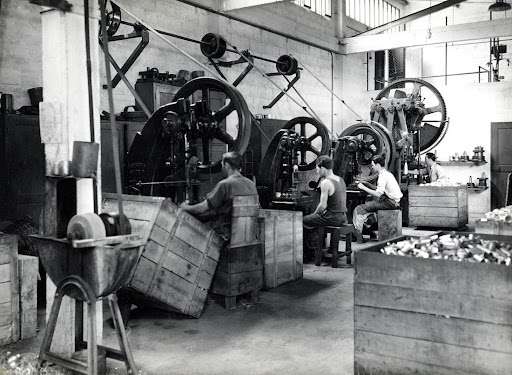

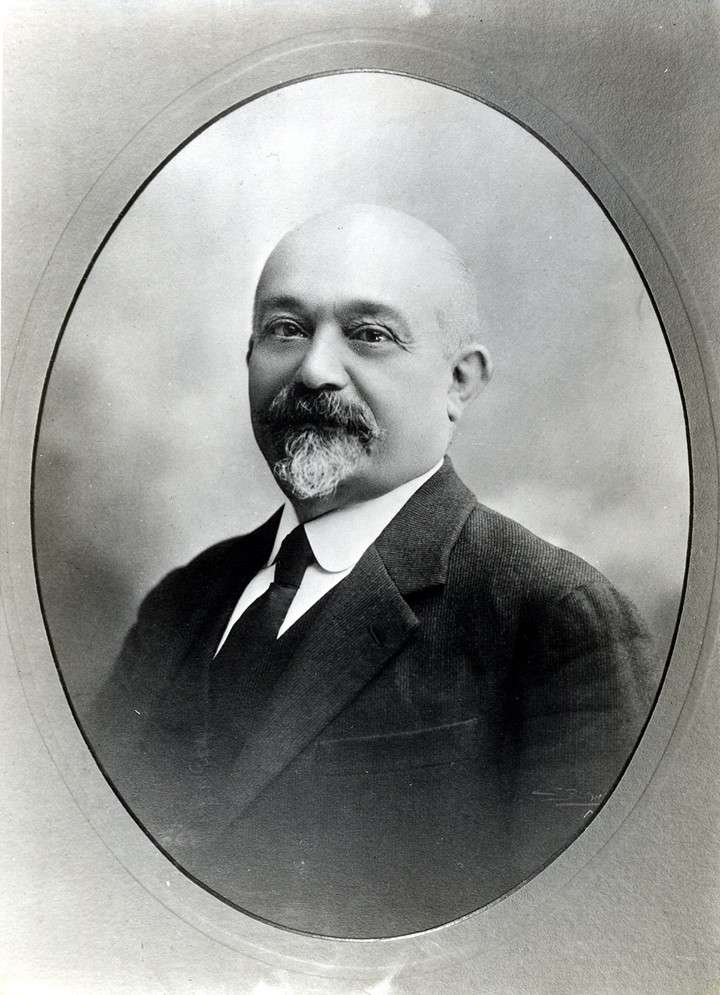

With the arrival in 1900 of the first steam factories in Grasse, and elsewhere in the west, arrived on the scene, Gustave Tournaire moved his ancestor’s workshop to premises of 600sq.m in Font-Laugière. As an engineer from the prestigious Arts & Métiers school, he developed the manufacture of tin-plated copper stills and vats for manufacturers in Grasse, French liquor-makers and the perfume-makers from all over Europe.

1920 – A FUNDAMENTAL SHIFT

From 1925 to 1930, with Marcel Tournaire at the helm, Tournaire S.A. harnessed progress in aluminium technology, to spearhead a revolution, introducing a range of packaging in state-of-the-art monobloc aluminium. Type 1 was born. Vitrification with firing and glazing was soon added to the range.

1950 – OPENING TO OVERSEAS

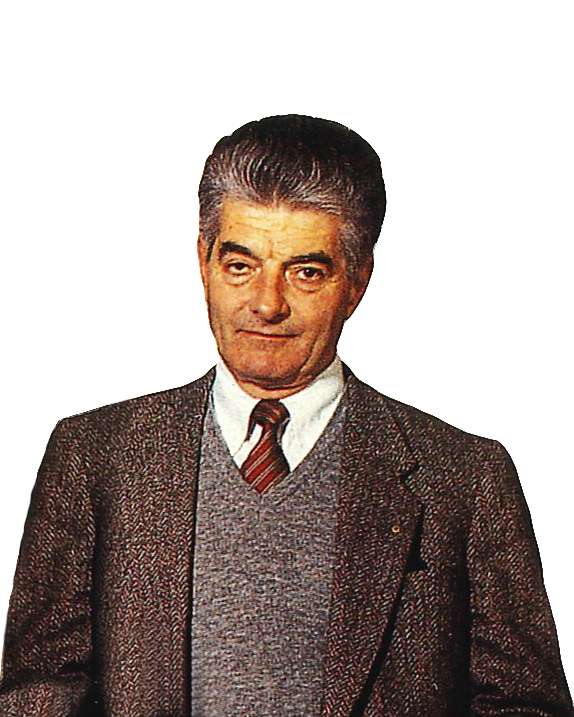

In the 1950s, the firm now directed by Jean Tournaire started catering to new markets. Tournaire packaging was used by the pharmaceutical industry to wrap sterile active ingredients, and also chemicals.

The development of the pharmaceutical and chemicals industries stepped up and in 1960, Marcel Tournaire invested in a plot of land in Plan-de-Grasse on which to build a new plant, still operating today. In 1965 René Tournaire industrialised the production of aluminium packaging with the introduction of the first extrusion presses and swaging machines.

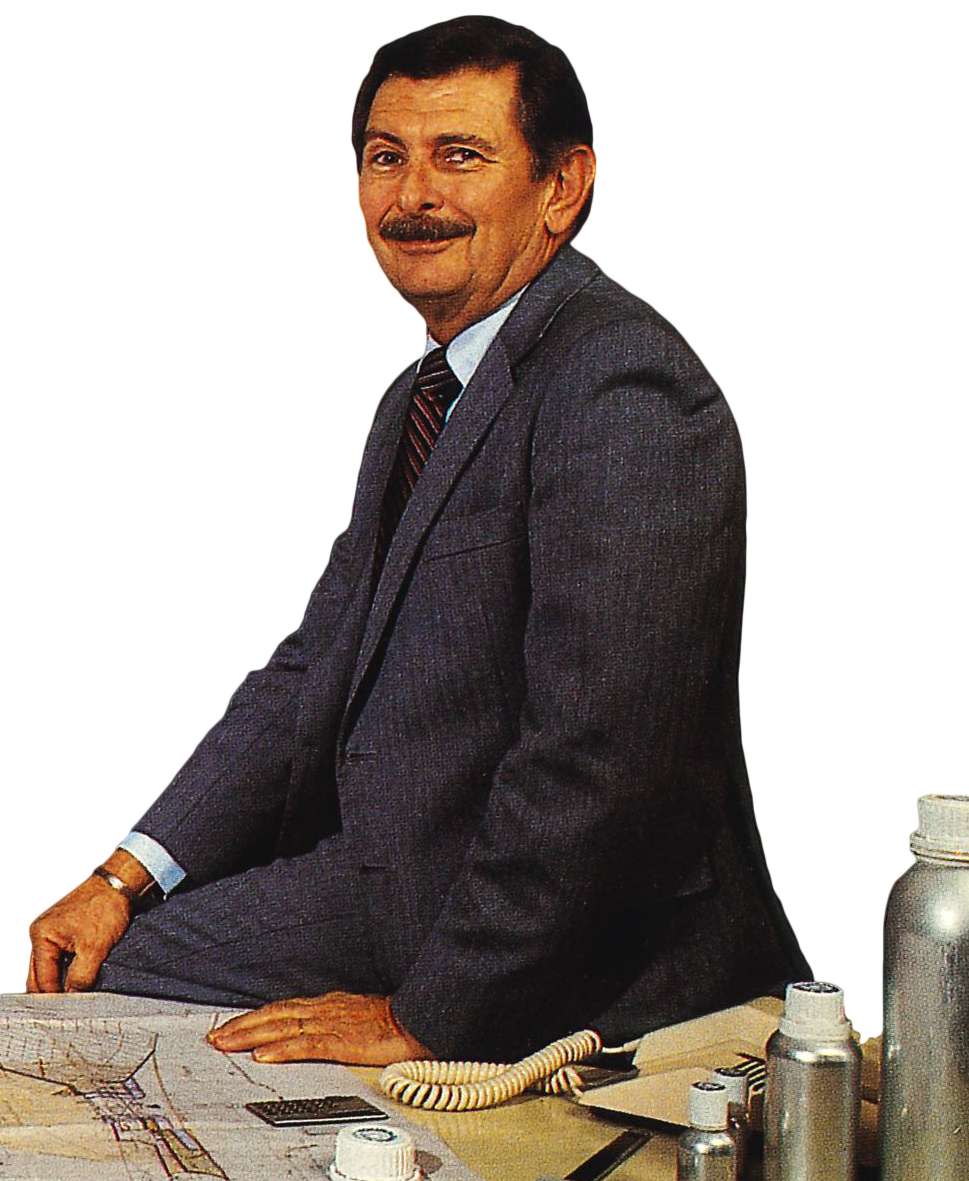

With Gilbert Tournaire as president and Jean-Pierre Forestier as CEO, packaging became Tournaire S.A.’s core business in the 1970s. Exports boomed: Sales Director Jean Tournaire expanded into Asia and the Middle East. Hugues Thibaud analysed and opened up the North American market with Tournaire S.A. partnering the firm O.Berk in New Jersey, and Xavier Arnoult became the first Exports Director, developing the European market.

In 1978, Tournaire S.A. introduced to the market its first tamper-proof mounting screw, designed by Jean Tournaire: Système Plus®. In 1980, Tournaire S.A. set up a plastic injection workshop to better control the performance of the closing mechanisms for its aluminium bottles.

in response to client demand, Tournaire S.A. expanded its savoir-faire in the 1990s to include co-extrusion blow moulding. The production of multilayer plastic jerry cans started up, adding further to the range of aluminium packaging. In 1993, Tournaire S.A. improved yet further the cleaning procedure, setting up an automated stripping and oxidation unit for aluminium packaging for active ingredients used in pharmaceuticals. This also helped to boost production capacity maintaining top quality. Further to several acquisitions, the site in Grasse was extended by 50% in 1995, with new premises being built to further develop the packaging business.

In 1999, Director Luc Tournaire founded the sales subsidiary TMM in partnership with a family business from the Jura, Millet Marius, in order to better serve clients working in agrochemicals. In 2003, the US subsidiary Elemental Container was created with the buyout of the subsidiary O.Berk International in New Jersey.

Tournaire S.A. earned ISO 9002 certification in 1996, then ISO 9001 certification in 2002 and lastly, ISO 14001 certification in 2003.

With a view to greater client proximity and to provide the best possible service, Tournaire S.A. created the industrial subsidiary Tournaire Plastic S.A.S on the former Kodak site in Chalon-sur-Saône in 2005. Thanks to this central location, Tournaire S.A. could quickly deliver its barrier packaging in coextruded plastic to its clients. This manufacturing subsidiary obtained ISO 9001 certification in 2008.

Lasting success, alongside social and environmental responsibility are major values underpinning S.A. Tournaire’s development. In 2011, Director Luc Tournaire set up the firm’s school, with the aim of documenting and teaching the firm’s very specific savoir-faire. This school also fosters the professional development of staff, helping them gain professional qualifications recognised by the French government, while maintaining jobs.

2010 – ROBOTICS FOR QUALITY

In 2013, the first robots came on the scene and the manufacturing lines were modernised, facilitating routine tasks and making them more reliable.

On the strength of its 185 years’ experience serving its clients, Tournaire S.A. created, the sales subsidiary Tournaire Asie Pacifique in Bien Hoa City, Vietnam in 2018, to reach out to its partners and boost its international footing.

From a tiny boilermaker’s workshop in Grasse in 1833 to the international group of today, Tournaire S.A. has ever developed and reinvented itself, lasting through two world wars, recessions and pandemics. Tournaire S.A. remains a family business with a rich and unique experience, ever adapting to its clients and its environment to remain a privileged, innovative partner to industries for sensitive materials.