Industry in France has regained real enthusiasm and a new dynamic thanks to a transformation of consumer trends but also to the recent strong support of public authorities. TOURNAIRE, like any heritage company, represents a part of French know-how. For many years, even in less favorable times, it is often the family-owned industrial companies that have defended their raison d’être to develop and perpetuate their activities at both regional and international levels, thus enabling this new dynamic.

Recently, several events have given concrete expression to this desire to promote “Made in France” to consumers, French and foreign buyers: “The Great Made In France Exhibition” which took place at the Elysée Palace on January 18 and 19, 2020, or the “Choose France” summit with more than 200 business leaders in Versailles.

This new impetus for the excellence of “Made in France” is the result and recognition of the long work of developing quality, innovation and transformation of French industries.

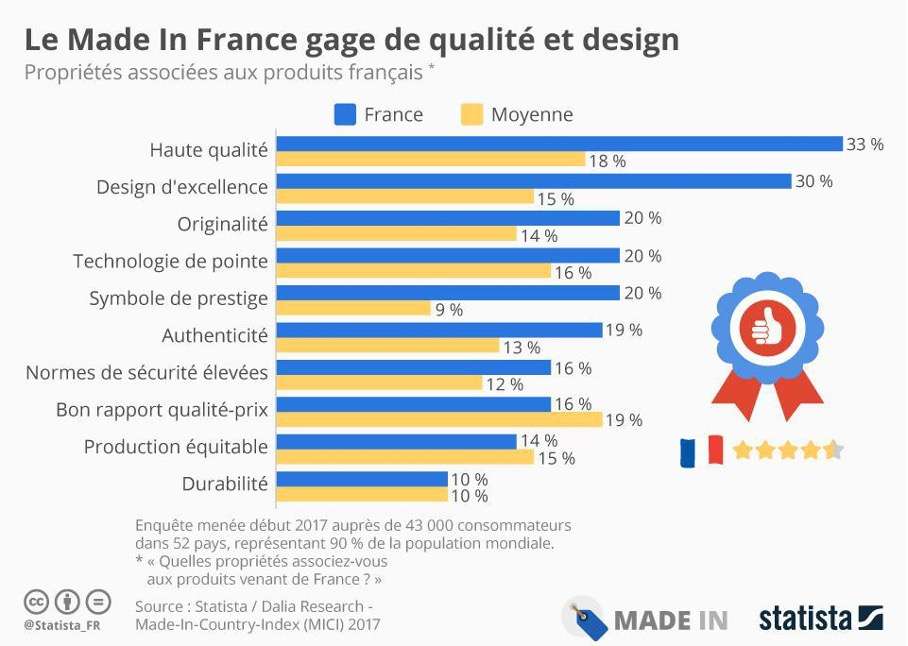

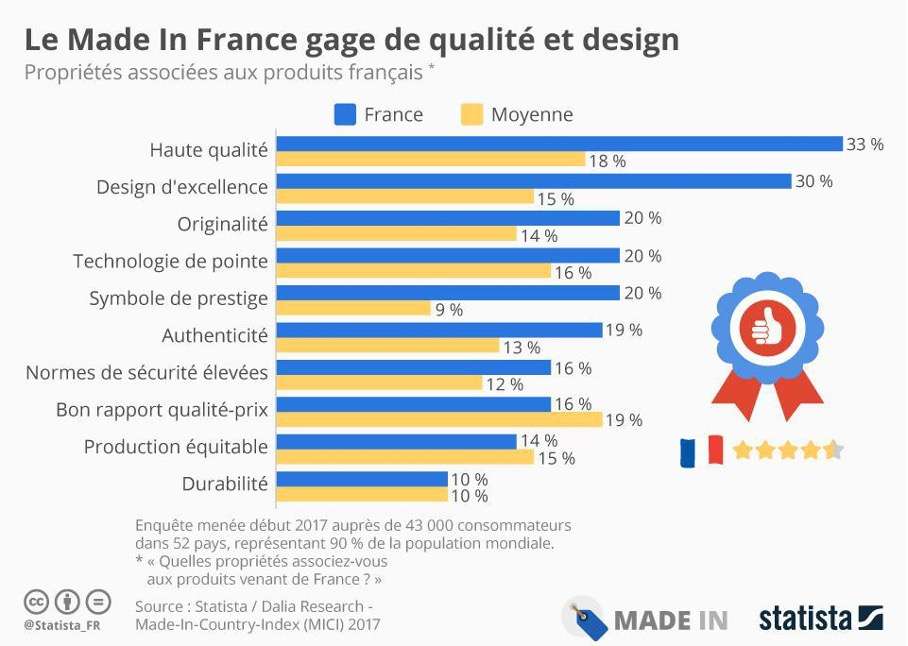

French excellence is appreciated by the French: “Companies prefer quality and know-how, consumers prefer employment and local production”, according to Les Echos of April 6, 2021 in its conclusion of the study on “Made in France” by Opinionway. Industrialists have succeeded in generating attachment to businesses in our territories among all those involved.

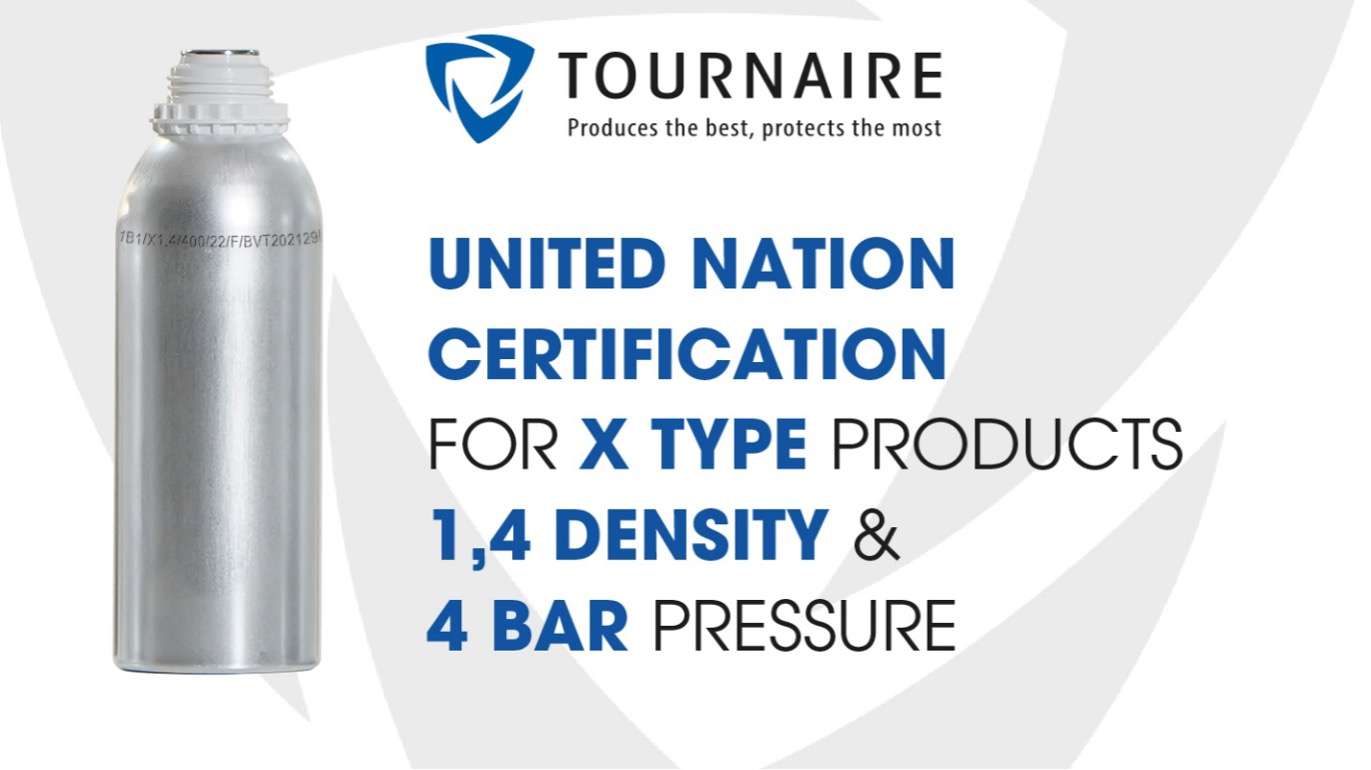

This ‘French’ quality is at the heart of the entire value creation chain at TOURNAIRE: from the initial sales advice to after-sales service, from production to delivery to the worldwide sales network. TOURNAIRE has developed its own metallurgy and surface treatment technologies in-house, which allow for the optimal production of its monobloc aluminium packaging. Its recently modernized quality laboratory accompanies the development of new products and ensures the quality of the production of existing packaging.

French excellence: a school with a long tradition and a culture of ‘le bel objet’.

Our rich cultural and industrial heritage has long made France the undisputed leader in ‘le bel objet’ (‘the beautiful object’) and the ‘art de vivre’ (‘art of living’).

French luxury manufacturers export to more than 180 countries. No other nation has such an influence, not even Switzerland or Italy (just behind). The French excellence that is praised commercially often obscures the changes and investments that manufacturers have made to improve their competitiveness in the face of increasing low-cost competition from Asian countries. It is a real challenge to increase its competitiveness, to invest in its production tool, while preserving product innovations and strengthening its brand. This is the challenge that TOURNAIRE has been meeting since 1833.

Indeed, French excellence for TOURNAIRE, in addition to meeting the increasingly strict regulatory requirements, is a foundation of the values of the company and its brand. The TOURNAIRE brand is thus synonymous with quality and serenity for its customers. This culture is carried by the Internal School ensuring the transmission of the company’s specific know-how. This has enabled TOURNAIRE to accompany its customers in more than 80 countries and to contribute for almost 190 years to the worldwide reputation of quality ‘à la Française’.

French excellence also means creativity, engineering and high-end products.

France excels in agriculture and agri-food, gastronomy, nuclear power, waste and water recycling, construction, transportation equipment manufacturers, armaments, aerospace, optics, chemicals, cosmetics, pharmaceuticals, perfumes, haute couture, and luxury goods. The two characteristic foundations of French excellence common to these industries are creativity and engineering.

TOURNAIRE is proud to showcase throughout the world countless products of French know-how in food, cosmetics, chemicals, pharmaceuticals, and the luxury goods that have made our territory in the Grasse region famous throughout the world: aromas and perfumes.

“In 2014, France reported a trade surplus for exports of aircraft and spacecraft, perfumes and cosmetics, its food industry and agricultural products, and in the field of waste management. The chemical industry is the second largest trade surplus (€9.4 billion) after aeronautics (€22 billion).”

French excellence: the image of the very high end carried by the world of luxury.

France traditionally enjoys an enviable image because it is spontaneously associated with the world of luxury. This is the result of France’s history, which has seen the birth of the world’s most powerful luxury brands. These houses represent no less than a quarter of the world market. Out of 270 prestigious brands, 130 are French (Ministry of Economy figures). This is another matter of creativity, quality, and engineering. TOURNAIRE has, for almost two centuries now, been working with these major players in the world of luxury.

This luxury sector has trickled down to many other French industries, from small and medium-sized companies to large corporations. For the perfume sector, it is in Grasse, the world capital of perfumery and the birthplace of Tournaire, that the majority of the players in this high-level industry can be found.

France is also about industrial excellence.

France is a land of industry. This is what emerges from the BPIFRANCE Lab study (April 2020): “85% of the industrial SMEs surveyed have their production sites in France. 25% of them even declare themselves to be ‘100% made in France’ (with only French production and supplies).

The manufacturing industry generates €223 billion in added value. This represents 10.2% of French GDP (source: Insee data 2015). It employs 2.815 million people, which represents 11.1% of total French salaried employment (source: Insee 2015 data).

France is the 7th largest industrial power in the world and the 3rd largest industrial power in Europe, just behind Germany and Italy. Manufacturing exports generate 436.4 billion euros (source: Customs, 2017 data) and represent 3.5% of global exports (source: WTO 2017). There are 213,303 industrial companies.“

France, the leading country for international investors.

According to the: “study of values associated with ‘Made in France’ by the General Directorate for Competitiveness of Industry and Services (2015)”, France continues to attract foreign manufacturers. France even ranks first in Europe for investment in production sites by foreign-owned companies, ahead of Germany! A more recent study shows that France has become the leading European destination for foreign investment in industry and R&D (source: Le Figaro – 20/01/2020).

French excellence: also a matter of territory.

French excellence helps to accelerate the reindustrialization of our territories, to develop local jobs and their economy. For some, it also helps reduce the carbon footprint to better fight against global warming. As Emmanuel Macron, President of the French Republic, said in his speech at the ‘Great Made In France Exhibition’: “Beyond promoting our know-how, it is a question of promoting a committed mode of consumption. Consuming French is an act of commitment to ecology (short circuit, reduction of our carbon footprint) and to the economy (supporting our workers and their territories). By choosing a product made in France and not made elsewhere, you have the power to support your country, your economy, your jobs, and your fight for ecology.”