Discover the news of the industrial group expert in the protection of sensitive and hazardous materials, as well as the list of trade shows and events in which Tournaire participates.

CERTIFIED PACKAGING FOR THE TRANSPORT OF HAZARDOUS MATERIALS : PRACTICAL GUIDE

CERTIFIED PACKAGING FOR HAZARDOUS MATERIALS

The transportation of hazardous materials is a critical and complex aspect of modern logistics, involving a multitude of factors such as regulation, safety, the environment, and technology. The significance of this activity is underscored by its role in sustaining our daily way of life, from the fuel powering our vehicles to the chemicals essential for various industries.

This practical guide has been developed to provide the most comprehensive and detailed overview possible on the various aspects of hazardous materials transportation. It aims to educate, inform, and guide professionals manufacturing or using hazardous materials or sensitive substances, logistics specialists, transportation companies, and any other stakeholders involved in this complex process.

Understanding the Complexities of Hazardous Materials Transportation

The Fundamentals of Hazardous Materials Transportation:

This section delves into the definitions of hazardous materials, the international and national regulations governing them, and the responsibilities of various stakeholders involved. Particular attention will be paid to the identification and classification of hazardous materials, crucial for their safe handling and transportation.

Certified Packaging:

Detailing the types of packaging used for the transportation of hazardous materials, with a special focus on aluminum solutions, our area of expertise. This part will address the advantages, specifications, and standards related to these packaging’s, highlighting why and how they ensure optimal safety.

Testing and Certification:

Here, we will discuss the testing and certification processes for packaging, essential to ensure compliance with safety standards. A focus will be placed on understanding and interpreting UN numbers, a critical aspect to ensure adherence to regulatory standards.

Tournaire and Its Innovative Solutions:

Introducing Tournaire, a leader in the field of UN certified aluminum packaging solutions. We will explore how Tournaire integrates innovation, performance, sustainability, support, and a global presence into its products and services.

Through this guide, we hope to not only provide essential information but also promote best practices, thus contributing to a safer and more responsible hazardous materials transportation industry. This article does not replace the internal rules specific to the company or the local, regional, or international regulations, which have the force of law. This guide is provided for informational purposes only and does not imply liability on the part of Tournaire.

The Fundamentals of Hazardous Materials Packaging and Transportation

Definitions and Regulations

The transportation of hazardous materials is a vital aspect of the modern industry, impacting numerous sectors from energy production to the manufacturing of chemicals and pharmaceuticals. These materials, due to their inherently sensitive properties, require strict safety measures set forth by national or international regulations, especially for their storage and transportation. This section outlines hazardous materials, their categorization, their role in the industry, and the importance of securing them during transport.

What is a Hazardous Material?

A hazardous material is defined by any substance that could pose a significant risk to health, safety, or the environment if not handled or transported correctly. These substances can be classified into different categories based on their nature and the type of hazard they present. Categories include explosive, flammable, toxic, corrosive, radioactive substances, among others. These classifications are crucial for determining appropriate safety measures and transportation protocols.

The Role of Hazardous Materials in Industry

Hazardous materials play a crucial role in a multitude of industries. For example, chemicals used in the manufacturing of medications are often classified as hazardous due to their toxicity, especially when concentrated. Similarly, the oil and gas industries rely on the secure transportation of flammable and explosive substances. Lithium batteries, widely used in electronic devices and vehicles, are another example of hazardous materials due to their potential for spontaneous ignition.

The Importance of Safe Transportation

Transporting these materials presents unique challenges and requires a high degree of responsibility and strict quality management to ensure regulatory compliance. Inadequate transportation can lead to serious accidents, environmental damage, and significant economic losses. Therefore, adhering to stringent standards, such as those established by the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and those set by other national or global regulatory bodies, is imperative.

Safety in the Transportation of Hazardous Materials

Safety in transporting hazardous materials is not limited to accident prevention. It also includes protecting workers, neighboring communities, and the environment. This encompasses practices such as proper staff training, the use of certified special packaging, adherence to transport quantity limits, and the implementation of emergency procedures in the event of an incident.

In summary, hazardous materials are ubiquitous in modern industry, and their secure transportation is critical for accident prevention and environmental protection. This reality underscores the importance of understanding the fundamentals of hazardous materials transportation.

Key Regulations for the Transportation of Hazardous Materials

The transportation of hazardous materials is governed by strict regulations at the international (UN), regional (EU), and national levels. These standards are crucial for ensuring the safety of individuals, environmental protection, and the prevention of risks associated with the transportation of these substances. In this section, we will examine the main regulations that govern this field, with a focus on the ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) and other relevant regulatory frameworks.

The ADR: An International Standard

The ADR, established in 1957 and updated in 2023, is primarily a European agreement (with 50 signatory countries) that sets international guidelines for the road transportation of hazardous materials. Its aim is to harmonize safety rules for transporting these substances across member countries, thus ensuring uniform practices and reducing the risk of accidents. More information can be found on the UN/ECE website which compiles various regulations.

Key Points of the ADR:

- Classification of Hazardous Materials: The ADR defines 9 different classes of hazardous materials, ranging from explosives to radioactive substances. This classification is crucial for determining appropriate safety measures.

- Packaging and Labeling Requirements: The ADR prescribes specific standards for the packaging and labeling of hazardous materials, ensuring that risks are clearly communicated and that packaging is robust and secure.

- Staff Training: The agreement emphasizes the need for proper training of drivers and all personnel involved in the transportation and handling of hazardous materials, including awareness of risks and knowledge of emergency procedures.

- Documentation and Transport Procedures: The ADR requires detailed documents to accompany the transport of hazardous materials, describing the nature of the goods, precautionary measures, and contact information in case of emergency.

Other National and International Regulations

In addition to the ADR, several other agreements or regulatory bodies play a significant role in controlling the transport of hazardous materials. Here are a few:

- RID (Regulation concerning the International Carriage of Dangerous Goods by Rail): Similar to the ADR but specific to rail transport.

- IMDG (International Maritime Dangerous Goods Code): Regulates the transport of hazardous materials by sea.

- IATA and ICAO for Air Transport: These organizations establish standards for the transport of hazardous materials by air.

- National Regulations: Each country may have its own laws and regulations that complement or reinforce international standards like the ADR, such as the DOT in the USA previously.

Impact on Safety and Risk Prevention

The strict enforcement of these regulations significantly impacts the safety of hazardous materials transportation. By establishing clear and uniform standards, they help prevent accidents and incidents while ensuring the protection of workers, the public, and the environment. Furthermore, they facilitate international trade by providing a common framework for the cross-border transportation of these substances.

In conclusion, regulations like the ADR play a crucial role in securing the transportation of hazardous materials. They are the cornerstone of a safer and more responsible global and local transportation system, essential for the effective management, handling, and safe transport of these high-risk materials.

Classification of Hazardous Materials

The classification of hazardous materials is a key element in managing the risk associated with their transportation. It enables the quick identification of the nature of hazards and the implementation of appropriate preventive and response measures. The different classes define specific risk categories, thereby guiding decisions regarding the packaging, storage, transportation, and handling of these substances.

-

Class 1: Explosive Materials and Objects

Definition: Substances, derivatives of substances, or combinations of substances that, through a chemical reaction, can release gases at high speed, pressure, and temperature, creating a risk of explosion. These materials require specific packaging to minimize risks.

Sub-classes:

- Mass explosion hazard.

- Projection hazard without mass explosion risk.

- Fire hazard with minor blast or projection effect.

-

Class 2: Gases

Definition: Compressed, liquefied, or dissolved under pressure gases, presenting various risks depending on their flammability, toxicity, or potential to cause asphyxiation.

Sub-classes:

- Flammable gases that can ignite quickly.

- Non-flammable, non-toxic gases that can cause asphyxiation.

- Toxic gases that can cause serious health effects.

-

Class 3: Flammable Liquids

Definition: Liquids or mixtures that release flammable vapors at temperatures below 60°C, posing a fire risk.

-

Class 4: Flammable Solids and Substances Dangerous When Wet

Sub-classes:

- Flammable Solids: These are solid substances that, under normal conditions, are likely to ignite easily after brief contact with an ignition source, such as friction, and continue to burn or smolder after the source of ignition is removed.

- Substances Liable to Spontaneous Combustion: These are substances that can ignite spontaneously in the presence of air without an ignition source, like exposure to ambient air.

- Substances that, in Contact with Water, Emit Flammable Gases: This group includes substances that, by reacting with water, can release flammable gases in dangerous quantities.

-

Class 5: Oxidizing Substances and Organic Peroxides

Sub-classes:

- Oxidizing Substances: These substances can cause or intensify a fire by releasing oxygen. They may also react violently with other substances, especially flammable ones.

- Organic Peroxides: Generally, these are organic compounds containing the bivalent -O-O- structure. They are thermally unstable and may undergo self-accelerating exothermic decomposition. Some may be sensitive to impact or friction.

-

Class 6: Toxic and Infectious Substances

Sub-classes:

- Toxic Substances: These substances can cause acute or chronic effects, or even death, when ingested, inhaled, or come into contact with the skin.

- Infectious Substances: These are substances containing pathogens (bacteria, viruses, parasites, fungi) that can cause diseases to humans or animals.

-

Class 7: Radioactive Materials

Definition: Contains radionuclides which the concentration or activity exceeds exemption levels.

-

Class 8: Corrosive Materials

Definition: Can cause severe damage to living tissues and corrode metals.

-

Class 9: Miscellaneous Dangerous Goods

Definition: Materials and objects presenting various hazards that do not fit the criteria of the other classes.

Importance of Classification for Safety

The precise classification of hazardous materials plays a crucial role in the prevention of accidents and incidents. It directly influences the methods of preparation, packaging, and transportation, as well as emergency procedures in the event of an incident. Understanding and adhering to this classification are essential for all parties involved in the transportation chain of hazardous materials.

Certified Packaging for Hazardous Materials

The safe transportation of hazardous materials requires the use of certified packaging specifically designed to minimize the risks associated with these substances. It is possible to certify substances of different natures: solids or liquids across the 9 classes of hazardous materials.

Types of Certified Packaging

Type A Packaging:

These packages are primarily used for transporting radioactive materials that do not generate significant amounts of heat. According to the specifications of the International Atomic Energy Agency (IAEA), they are designed to withstand normal transportation conditions without releasing radioactive content.

Type B Packaging:

These are intended to contain more hazardous radioactive materials, such as those used in nuclear reactors. These packages are designed to withstand severe accidents during transport, including fires, submersion underwater, and falls. The IAEA regulations specify strict criteria for their design and testing.

Type C Packaging:

Specifically designed for air transport, these packages are used for highly active radioactive materials. They must meet extremely rigorous requirements, including the ability to withstand high pressures and extreme temperatures.

Drums, Jerricans, and IBC Containers:

These versatile packages are used for various classes of hazardous materials. Their design varies depending on the nature of the content – drums for liquids, jerricans for small volumes, and IBC containers for larger volumes. They are chosen based on their material, capacity, and resistance to transportation conditions.

Aluminum Packaging:

Aluminum offers unique advantages for the transportation of hazardous materials. It is strong, lightweight, corrosion-resistant, and ensures excellent seal and container integrity. These characteristics make aluminum packaging ideal for a wide range of hazardous materials, from flammable liquids to corrosive substances.

Standards and Certification of Packaging for Hazardous Materials

Packaging Selection and Customization

The choice of packaging for hazardous materials is guided by the flow of goods, the type of product to be packaged, and its final use. Depending on the requirements, different types of packaging and certifications are used. For example, Bulk Chemicals require Large Bulk Containers (IBCs) of 1000L that travel without overpackaging with “stand alone packaging” type certifications, while finished products are often packaged for transport in “combination packaging,” for example, metal flasks, which are then placed in cardboard boxes for transport. In the latter case, the “box and can” set is certified.

The “stand alone” certification requires higher performance criteria. Recently, for sensitive products and medium-sized packaging, it is common to require both stand alone and combination certification, even if these packages are always transported in boxes. This dual certification is considered a safety guarantee, especially at the end of the supply chain, which constitutes a sales argument.

Every industry, especially in the chemical and pharmaceutical sectors, incorporates the Dangerous Goods Transportation (DGT) regulations into the packaging specifications, requiring constant and reliable expertise and certified suppliers.

Testing and Certification of Packaging

Certification Process

Packaging intended for the transportation of hazardous materials, as well as packaging manufacturers, are subject to a rigorous certification process to ensure compliance with international safety standards. These two processes are essential to guarantee that these packaging’s can withstand the challenges and constraints of transportation environments without compromising the safety of people and the environment. Only organizations officially recognized by the authorities can issue Approval Certificates, which are indispensable for the transportation of dangerous goods and to conduct audits on the holders of these certificates. It is crucial to ensure, when purchasing and selling certified packaging, that the Approval Certificates are valid and up-to-date.

Conformity Assessment

Initially, each packaging is assessed for its drop resistance, seal integrity, and pressure tolerance. These tests are of uppermost importance, especially for aluminum packaging, chosen for its lightness and corrosion resistance, frequently used in the transportation of hazardous materials.

Selection of Packaging and Overpacks

Before testing, a careful selection of packaging types and sizes, and overpacks is made based on the flow and type of hazardous material to be transported (solid, liquid, gas). This choice also depends on the classification of the packaged product and its final use. The range of packaging and overpacks is vast: for bulk transport, Large Bulk Containers (IBCs) such as 1000L pallet boxes are common, as well as metal drums from 30L to 200L, and for smaller flows of sensitive materials, aluminum cans and bottles from 5L to 32L. For finished products, smaller packaging such as metal bottles and flasks are used, which can be grouped in cardboard boxes for protection during transport.

Determination of the UN Code and Hazard Group

A key step in the process is determining the UN code for each chemical component of the product. These codes are found in tables within the ADR and other regulations. They define the product’s associated constraints and hazard group:

- Group I : Very dangerous materials

- Group II : Moderately dangerous materials

- Group III : Less dangerous materials

Role of Accredited Laboratories

In France, accredited laboratories such as APAVE, BVT, LNE et LEREM, play a decisive role in the certification of packaging. A list of accredited bodies can be consulted on French Ministry of Ecology’s website. These institutions perform a series of mandatory tests, including seal integrity, drop, pressure resistance, and stacking tests, to ensure that the packaging meets the strict safety requirements defined by international agreements. The BAM in Germany is another renowned laboratory in this field. Accredited laboratories are also responsible for regularly auditing the holders of Approval Certificates, issuing a Certificate of Conformity on these occasions, confirming that the company has implemented the manufacturing and quality control measures to comply with regulatory prescriptions related to packaging for the transportation of hazardous materials. Only these accredited laboratories are able to issue Certificates of Conformity and UN Approval Certificates which are recognized worldwide.

Obtaining the UN Number

Once the tests have been passed, a Certificate of Approval with its unique UN number is assigned to the unitary or combined packaging, specifying materials, types and components of packaging, method of assembly, hazard group, maximum permitted density and pressure, as well as other crucial technical information. This Certificate and the UN number are a guarantee of conformity and reliability for end users, transporters and the authorities of each country crossed.

Key role of Certification

The certification process and adherence to the instructions in the Approval Certificate ensure that the packaging used for the transportation of hazardous materials is suitable for its content and mode of transport, thereby reducing the risks of accidents or contamination during transport. It is essential that these procedures are rigorously followed to maintain the high safety standards required in the hazardous materials transportation field.

This certification process for packaging and packaging suppliers ensures that the packaging not only meets safety requirements but also the specific needs of industries that rely on these materials for their daily operations.

UN Certification Renewal

The renewal of UN certifications is an essential step to ensure the compliance of packaging dedicated to the transportation of hazardous materials. These certifications, generally valid for a period of five years, must be renewed to guarantee adherence to the most recent safety standards. This process involves periodic testing and reevaluation of the packaging to confirm its durability and integrity. Regular monitoring is crucial to maintain quality and safety standards and to adapt to the sector’s technological and regulatory developments.

Understanding UN Numbers

After testing, laboratories assign a UN number on the Approval Certificate, which must appear alongside the hazard pictograms on the primary packaging for individual certification and on the grouping carton for combined packaging. This number encodes essential information, which is important to know and master in detail to ensure its compliance with the transported product.

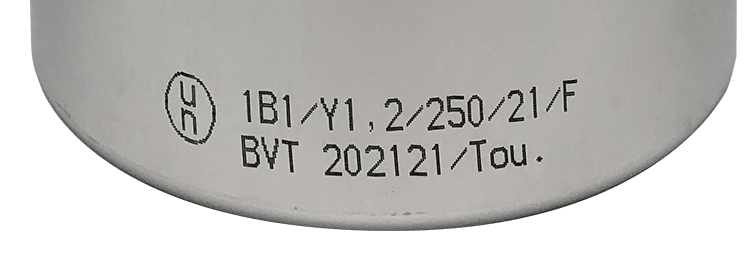

For instance, in the aforementioned case next to the UN (United Nations) logo, the identification “1B1/Y1,2/250/21/F/BVT 202121/TOU.” should be deciphered as follows:

- The type of packaging (e.g., 1B1 for a partially openable aluminum packaging),

- The hazard group (X for Groups I, II, or III; Y for Groups II and III; Z for Group III only),

- The density here is 1.2 or the maximum approved mass for solid product certifications,

- The test pressure in kPA – here 250, equivalent to 2.5 bar,

- The manufacturing year – here 2021,

- The manufacturing country here F for France,

- The identifying laboratory here BVT that conducted the tests and the report number,

- The manufacturer’s identification – here “Tou” for Tournaire.

Each segment of this number thus provides essential information on the physical limits of the product to be packaged and on the packaging’s compliance, thereby ensuring safe and regulatory transport of hazardous materials.

Which Partner for the Packaging and the Transportation of Your Hazardous Materials?

The transportation of hazardous materials is a demanding field that requires highly qualified partners, certified by governmental bodies, thus capable of mastering the technical and regulatory constraints specific to this sector. These partners must have a deep understanding of the various types of packaging and overpacks, as well as the transported products, and constantly stay up-to-date with UN and ADR regulations, even anticipating major evolutions.

When choosing a supplier for hazardous materials packaging, you can opt for a manufacturer or distributor, depending on your specific needs. A distributor offers a wide range of certified packaging in stock and provides the necessary approval certificates, ensuring the validity and compliance of the used packaging.

Manufacturers bring deep technical expertise, thanks to a long history in the industry or through their specialization in certain categories of packaging or materials. These players offer a wide variety of certified packaging, as well as the ability to create customized solutions to meet specific needs. With their experience in designing and manufacturing packaging, these manufacturers ensure strict adherence to quality and safety standards through procedures regularly checked by accredited organizations and their clients.

Tournaire – Leader in Aluminum Packaging Solutions

Our History & Experience

Tournaire, established in 1833, is recognized for its expertise in aluminum packaging solutions, especially in the transportation of hazardous materials. Innovation, at the heart of their strategy, is reflected in their avant-garde approach to metal forming and surface treatment. This technical expertise allows for the development of packaging that meets stringent safety and performance requirements.

Tournaire’s reputation is built on its commitment to excellence and quality. The seamless aluminum packaging, lightweight and durable, offers an optimal solution for the safe transportation of hazardous materials, thus minimizing the risks of leakage or contamination.

Our Commitment

Tournaire’s commitment to sustainability and social responsibility is deeply embedded in its operations. Protecting people and products is at the core of this approach, recognizing that securing hazardous materials directly contributes to environmental protection. In doing so, Tournaire works not only for immediate safety but also for the preservation of the environment for future generations.

Tournaire’s customer service is remarkable, offering comprehensive support from material selection to compatibility testing, through regulatory support. Their ability to maintain a large inventory and adaptive logistics ensures the continuous availability of packaging solutions, a critical aspect in the field of hazardous materials.

Their global presence, supported by a rich history and ISO 9001 and 14001 certifications, attests to their expertise and reliability. Tournaire stands out for its ability to offer customized solutions for the transportation of sensitive materials, strictly adhering to UN and ADR standards to ensure safe transport in compliance with international regulations.

About us

In summary, Tournaire embodies the balance between innovation, technical expertise, social responsibility, and commitment to quality and sustainability. Their holistic approach to the transportation of hazardous materials, focused on safety, efficiency, and environmental protection, positions them as a partner of choice in this highly demanding sector.

Conclusion

Managing the transportation of hazardous materials is a significant concern for safety, environmental preservation, and value protection. We hope this purely informative guide has shed light on the importance of a thorough understanding of all aspects of this complex process. It indeed spans from the classification and regulation of hazardous materials to the strict requirements for packaging and certification. By emphasizing the importance of the appropriate selection of packaging, especially aluminum for its robustness and safety, we have underscored the importance of choosing solutions that are adapted and compliant with regulatory requirements.

Tournaire, with its rich history and recognized expertise in the manufacturing of seamless aluminum, positions itself as a vital partner in resolving issues related to the transportation of hazardous materials. Our commitment to innovation, quality, sustainability, and social responsibility reflects our mission to protect not only the hazardous materials themselves but also the people and environment surrounding them.

Ultimately, understanding and managing the transportation of hazardous materials is crucial for ensuring safety and preserving our planet. At Tournaire, we are dedicated to supporting our clients in these challenges by providing reliable and innovative packaging solutions, tailored to their specific needs. Our expertise, derived from over 190 years of experience, is the guarantee of a solid and lasting partnership, for a safer and more responsible future.

Appendices

Glossary: Key to Understanding

Materials

Hazardous Material: A substance that poses a potential significant risk to health, safety, or the environment if not properly handled or transported.

Explosive/Flammable/Toxic/Corrosive/Radioactive Substances: Categories of hazardous materials classified according to the nature of the danger they present.

The Transport

ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road): An international agreement governing the road transportation of hazardous materials, aimed at standardizing safety regulations at the European level.

IMDG (International Maritime Dangerous Goods Code): International rules governing the transportation of hazardous materials by sea.

IATA (International Air Transport Association): An international organization establishing standards for air transportation, including the transportation of hazardous materials.

RID (Regulation concerning the International Carriage of Dangerous Goods by Rail): Regulation governing the rail transportation of hazardous materials, similar to ADR but specific to rail.

Certified Packagings

Certified Packaging: A container designed for the transportation of hazardous materials, certified to comply with international safety standards.

Seamless (or one-piece / monobloc) Packaging: A type of packaging manufactured in a single piece, without joints or welds, offering increased safety and integrity for the contents.

UN Number (United Nations Organization): A unique identification code assigned to each hazardous substance, defining its nature and associated risks.

IBC (Intermediate Bulk Container): A large container used for the bulk transportation and storage of liquids, solids, or semi-solids.

Type A/B/C Packaging: Categories of packaging for radioactive materials, classified based on their strength and ability to withstand extreme conditions.

ISO Certification: An international standard indicating that an organization meets quality and environmental management requirements.

Cleanliness (Three levels at Tournaire):

- Microbiological Cleanliness: Monitoring and control of living contaminants to ensure sterility.

- Chemical Cleanliness: Monitoring of chemical pollutant levels to maintain unmatched chemical cleanliness.

- Particulate Cleanliness: Monitoring of significant size particles to ensure the purity of the contents.

Seal Integrity: The ability of packaging to prevent leaks or exposure of its contents.

Pressure Resistance: The ability of packaging to withstand internal or external pressures without failure.

Compliance and Performance: For Tournaire, compliance with regulations is considered a minimum. The company goes beyond by focusing on performance, taking additional safety margins to provide peace of mind to clients. Tournaire also anticipates stricter future standards, thus ensuring its clients remain compliant and ahead of regulatory requirements.

Tamper-evidence and Anti-counterfeiting: Features of packaging designed to prevent unauthorized opening or falsification of the contents.

L’Environnement

Sustainability: The practice of using resources in a way that does not compromise the needs of future generations.

Social Responsibility: : A company’s commitment to act ethically and to contribute to economic development while improving the quality of life of employees and society.

Life Cycle Analysis: Evaluation of the environmental impact of a product throughout its lifespan, from production to disposal.

References and Sources: For Further Reading

Sources

- International Atomic Energy Agency (IAEA) for the design criteria of Type A, B, and C packaging.

- ADR regulations for the specifications of drums, jerricans, and IBC containers.

- Properties of aluminum based on studies in metallurgy and materials engineering.

- • Regulation of the Transportation of Dangerous Goods (TDG)

- Packaging Approval Procedures by Accredited Laboratories (BVT, LNE, LEREM, BAM)

- International Standards on UN Codes for the Packaging of Dangerous Goods

- • Regulation of the transportation of dangerous goods French Ministry of Ecological Transition

- Dangerous Goods – TMD Bretagne

- • The 9 Classes of Dangerous Goods – CCOHS

- • Regulation (EU) 2020/878 – EUR-Lex

- Official website of the European Commission

- Official website of the UN

- Official website of IATA

- Official website of ADR

- Official website of RID (Regulation concerning the International Carriage of Dangerous Goods by Rail)

- Official website of the IMDG(International Maritime Dangerous Goods Code)

These sources provide detailed and up-to-date information on regulations and practices concerning the transportation of dangerous goods, ensuring a solid foundation for understanding the sector’s complexities.

Want to Learn More? Contact the Tournaire Experts

Our guide has provided you with a comprehensive overview of the transportation of dangerous goods and Tournaire’s excellence in delivering secure and innovative packaging solutions. If you wish to delve deeper into how our products and services can meet your specific needs, we are here to assist.

Our experts are available for personalized consultations.

Visit our contact form to share your needs and questions. A member of our team will respond as soon as possible to provide expert advice, tailored to your industrial context.

Tournaire is committed to not only providing high-quality products but also support and expertise that make a difference. Contact us today to advance your project with a partner you can trust.