Discover the news of the industrial group expert in the protection of sensitive and hazardous materials, as well as the list of trade shows and events in which Tournaire participates.

The Technology Behind Packaging: How Technical Innovation is Revolutionizing the Protection of Our Customers’ Products

Introduction

Ensuring the protection of materials during transport is a major challenge. Packaging, which fulfills this function, is far more than just a container. It plays a fundamental role in the value chain of our clients’ products by ensuring their protection, extending their shelf life, facilitating transport, informing consumers, and conveying the brand image. Over the centuries, its function has evolved in response to major technological upheavals. Today, in a world where safety, traceability, and sustainability requirements are increasingly stringent, technical innovation is radically transforming the packaging landscape.

Tournaire Group’s aluminum and stainless steel packaging forms a fundamental pillar of our offering, designed to ensure the safety, preservation, and integrity of sensitive and/or valuable and/or hazardous products. Our packaging is engineered to meet the strict requirements of various industrial sectors, including perfumery, cosmetics, healthcare, and specialty chemicals. At Tournaire, for over 190 years, we have met these needs through the technical innovation of our aluminum packaging. Innovation is in our DNA. It is a value as instinctive and vital as breathing—accessible to everyone in their daily lives. We like to say that “We innovate the way we breathe” (Olwen Wolfe – 2007).

This “white paper” explores the many facets of this transformation. After presenting our definition of innovation, we will look back at the historical evolution of packaging, before highlighting the journey of the Tournaire Group. We will provide a detailed description of the specific features of our packaging, along with an explanation of our technical and scientific approach, which has always been shaped by our markets and clients. In this section, we will showcase some of our most innovative and impactful projects. Finally, we will introduce our packaging of the future: the OMNI+® range, which addresses the crucial challenges of sustainability—an essential issue for the development of tomorrow’s packaging.

Innovation, Tournaire’s historic tool for adaptation

Throughout the ages, innovation has emerged as the fundamental driving force behind the ability of industrial players to reinvent themselves in the face of new challenges. A tool for progress, excellence, and resilience, it has been part of Tournaire’s DNA since the company’s founding in 1833. Passed down through generations, it has enabled us to adapt to and anticipate the challenges of the past for both our equipment and packaging divisions.

In 2022, in a context of global transformation in industrial and environmental expectations, we made the strategic decision to refocus on our core business by divesting our equipment division. One year later, we took a second major step by selling our multilayer plastic packaging business. And in September 2024, the Tournaire Group expanded its range and footprint in North America with the acquisition of INOVAWELD, a Canadian company specialized in laser-welded stainless steel packaging. These three decisions marked a significant milestone in the history of Tournaire, allowing us to focus our resources, expertise, and capacity for innovation on the industrial metal packaging sector—a promising area with strong potential for ecological transition.

Our commitment to innovation is crystal clear: to design packaging solutions that are ever more efficient, sustainable, and responsible. Aluminum is an outstanding material from an environmental perspective: it is infinitely recyclable without any loss of its mechanical properties or performance, making it a valuable ally in a circular economy approach. An aluminum package can be remelted, reprocessed, and reused continuously, while maintaining its strength, lightness, and barrier properties. In contrast, plastic must be described as “downcyclable,” since its “recycling” results in a gradual degradation of its qualities. This downcycled plastic is often used to manufacture lower-grade or single-use products before inevitably ending up in landfills or incinerators. And that is not the end of its life—micro- and nanoplastics (MNPs) resulting from plastics are extremely persistent in the environment (lasting hundreds to thousands of years) and are now found everywhere.

Thus, the choice of aluminum for packaging reflects a strong commitment to sustainability, consistent performance, and respect for natural resources—clearly contrasting with the structural limitations of petroleum-based plastics.

Beyond the material itself, we have been transforming our entire industrial process since the 1960s: high-performance packaging requires high-performance industrial capabilities. Our innovative industrial facilities ensure consistent quality, high mechanical reliability, and maximum safety at every stage of production—from raw aluminum to the delivery of finished products. Today, our packaging production lines are equipped with high-precision machinery capable of large-scale manufacturing of uniform containers with extremely tight tolerances. This ensures not only perfect compatibility with automated filling systems but, more importantly, minimizes the risk of defects that could compromise the integrity of the packaged product. Technical innovation here enables the development of tools and machinery tailored to meet all the functional expectations of our packaging. It also allows for the automation of rigorous quality controls throughout the production process, ensuring a consistency that only technology can deliver.

As early as 2013, we initiated a thorough reflection on the composition of our packaging. A simple yet essential question arose: why maintain a crimped plastic sleeve on an aluminum body?

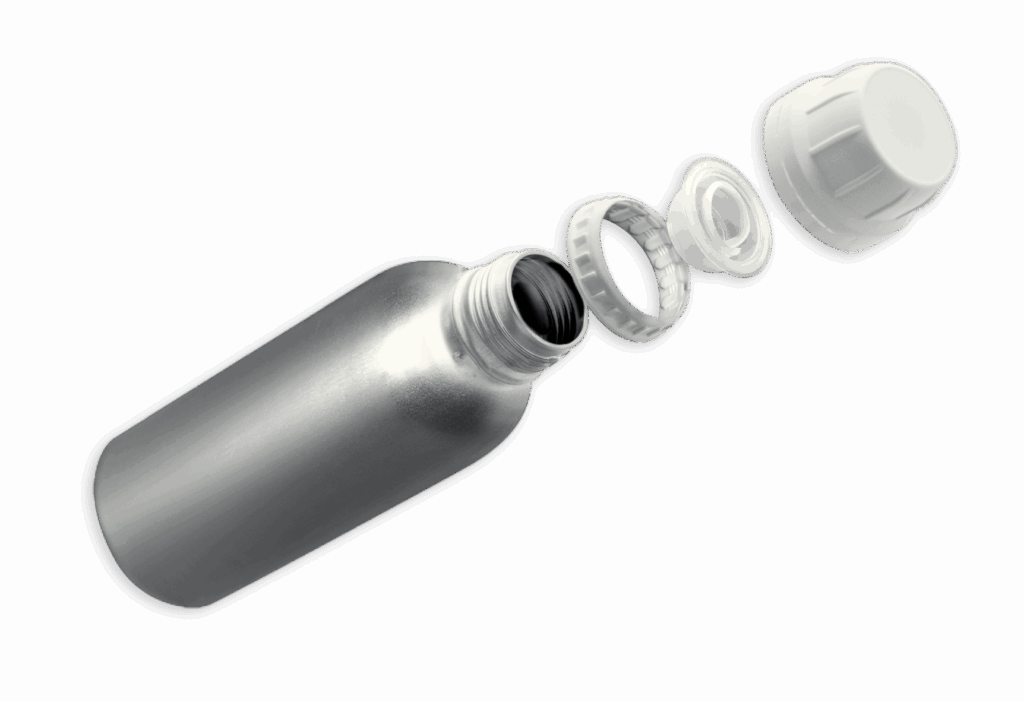

This combination of materials, which are difficult to separate, complicated recycling and ran counter to the eco-design principles we aimed to implement. We therefore considered a more sustainable alternative: designing a closure system that could be more easily dismantled, allowing the entire package to enter an effective recycling stream. A true example of the “Design for Recycling” approach, the OMNI+® closure was born.

In this context, innovation goes beyond technology and sustainability. It is also organizational, human, and cultural. It lies in our ability to bring our teams together around a common project, to collaborate with our clients in anticipating their needs, and to evolve our production methods toward greater efficiency and energy sobriety. It is also reflected in our willingness to embrace collective intelligence by integrating external expertise, forming academic and industrial partnerships, and investing in applied research. For the past two years, we have been actively pursuing initiatives to meet these needs, always with the ultimate goal of serving our clients.

Innovation at Tournaire is organized in a fairly classic way. It is built on project management that begins with the idea phase (observation and active listening, enabling us to define intentions, objectives, and challenges) and continues through to customer delivery (SOP = Start Of Production). There are three types of projects: technological R&D projects, Proofs of Concept, and industrial product development projects, all managed using a “hybrid” project management model (V-cycle and/or Scrum, depending on the type and stage of the project).

This hybrid model, combining the structured V-cycle with the iterative and collaborative Scrum method, has proven to be particularly effective for us. The V-cycle offers a clear and sequential roadmap with precise documentation and control over timelines. Scrum, as an agile method, fosters responsiveness to changing internal and external needs while enhancing team engagement. This combined approach allows us to stay on schedule and within budget while introducing agility and creativity into execution. Ultimately, hybrid project management is a compromise management model. It allows the Tournaire Group to remain agile, competitive, and effectively innovative.

Since the 2020s, Tournaire has carried out between 40 and 50 projects per year, with 85% in 2025 aligned with the 3R decree (Reduce, Reuse, Recycle) of the AGEC law (Anti-Waste and Circular Economy Law). Some of these projects are grouped into nine programs, all eligible for France’s Research Tax Credit (CIR). This eligibility reflects compliance with rigorous criteria defined by the French administration, particularly in scientific and technical innovation. CIR projects must aim to overcome technological barriers or advance knowledge in the relevant fields. Being CIR-eligible is therefore a mark of rigor, ambition, and excellence. Furthermore, expectations have evolved in recent years: projects must now incorporate environmentally respectful solutions based on sustainable and high-performance technologies.

In summary, at Tournaire, innovation is not just an invention or a technical novelty. In this sense, the equation innovation = invention + ecology + added value (economy) is highly relevant in today’s context, where the value of innovation is increasingly measured by its contribution to a more sustainable world. Far from being a passing trend, innovation is now a true strategic lever for overall performance.

Let us call it: eco-eco-innovation, or eco² innovation!

The Evolution of Tournaire Packaging: From Simple Container to High-Tech System

The history of packaging dates back to ancient civilizations, which used natural materials such as leaves, animal skins, pottery, or plant fibers. The primary objective was to contain or protect goods during transport or storage.

With the Industrial Revolution, mass production brought about the emergence of the first standardized packaging using basic materials such as wood, metal, glass, or cardboard. In addition to containing and protecting products during large-scale logistics operations, the main goal of these early industrial packages was to prevent leaks, contamination, or product loss. However, their functionality was limited. They were often heavy, poorly sealed, or ill-suited to the specific constraints of certain products.

It was in this context that, in the 1930s, a perfumer from Grasse approached Marcel Tournaire (representing the third generation of the family) to develop small “estagnons.” Used in southern France and Provence, the estagnon is a cylindrical container made of tin, copper, or tinned iron, intended to hold essential oils or aromatic essences. He identified aluminum as a material offering excellent performance in multiple applications. It is lightweight (reducing CO₂ emissions during transport), corrosion-resistant (naturally forming a layer of alumina, Al₂O₃), strong, infinitely recyclable (with low energy cost), and—above all—an effective barrier against air, humidity, light, oxidation, and other external factors that can degrade the product.

Beyond choosing aluminum, he also had the visionary idea of using a monobloc structure for this packaging—manufactured from a single piece without any welds. This innovative design offered numerous advantages: enhanced protection against leaks, cracks, and contamination by eliminating the weak points typically found at material joints. This approach ensured optimal sealing and high mechanical resistance, even under extreme transport or storage conditions. This was the first major technical innovation in Tournaire’s packaging history. This visionary choice enabled the company to stand out from the beginning in the field of technical packaging for sensitive and hazardous materials. It also laid the foundation for an engineering philosophy focused on product safety and container durability—principles that continue to guide us today.

The 20th century saw the rise of plastics—particularly polystyrene and polyethylene—which revolutionized the packaging industry due to their low cost, light weight, and adaptability. This era also witnessed the diversification of formats (PET bottles, thermoformed trays, etc.) and the rise of marketing-driven packaging. However, plastic is porous and, at equal volume, performs poorly when it comes to UN certification for the transport of hazardous materials. The PPWR regulation (Packaging & Packaging Waste Regulation), adopted at the end of 2024, aims to harmonize packaging management and improve packaging waste treatment within the EU by prioritizing circular economy principles and recycling, particularly through the reduction of plastic use.

Among Tournaire’s most significant innovations is the SYSTEM PLUS® closure, developed in the 1980s. This technological breakthrough involved combining aluminum with plastic—an audacious choice at the time—designed to meet the highest standards of sealing performance. Tournaire undertook to comply with international agreements on the transport of dangerous goods. This closure quickly became a benchmark solution for the safe transport of hazardous, valuable, or sensitive substances.

Today, it remains widely praised by our clients. With formats ranging from 19cc to 32 liters, we offer the broadest and deepest product range on the market. To meet this challenge, Tournaire had to expand its competencies by integrating the scientific and technical knowledge of plastics processing, while building on its historical expertise in metallurgy and precision mechanics. This ability to combine disciplines and innovate with agility embodies the company’s spirit of excellence—an enduring force that continues to drive our teams today.

At the same time, chemical and pharmaceutical industries quickly encountered the limitations of traditional materials: chemical reactions with the contents, porosity, degradation due to light or oxygen, high mass, and costly multi-material solutions. Once again, Tournaire was the first, in the 1980s, to offer a “pharma” closure—known as Type 8—with a chlorobutyl elastomer stopper specifically designed for pharmaceutical active ingredients.

Protecting a product goes beyond ensuring tight sealing, container strength, or chemical inertness. It also requires considering how the packaging performs under various conditions: during transport, in storage facilities, across different climates, or within complex logistics networks. Innovation now allows us to design packaging capable of withstanding such constraints. The cylindrical shape, due to its geometry, offers a natural rigidity that differs from rectangular formats, which are more prone to deformation at the corners. Other packaging shapes we offer are optimized to avoid structural weak points. Wall thicknesses are fine-tuned to reinforce robustness where it is most needed (aligned with the “Reduce” principle of the 3Rs concept from the IPCC), and the overall design ensures the product remains stable throughout its entire lifecycle.

Our history—initiated by those who came before us—is the foundation of our current ambitions. Thanks to their vision, expertise, and high standards, we have developed a unique know-how in technical packaging for B2B markets. Today, this accumulated experience enables us to remain at the forefront of innovation and to offer reliable, sustainable solutions tailored to even the most complex needs. We are proud of the expertise built over more than 190 years, while staying true to the values of excellence, performance, and commitment that have always guided our company.

Tournaire, Pioneer and Leader in High-Performance Packaging Innovation

In the 1930s, Tournaire achieved its first major innovation in the field of packaging with a monobloc aluminum canister. But packaging performance also depends heavily on the closure system. A high-quality canister body is not sufficient—it must be equipped with a reliable sealing solution. In this context, during the 1980s, Tournaire made a second significant breakthrough with the development of the SYSTEM PLUS® closure, marking a turning point in terms of safety and performance. Since then, many innovations have followed, all driven by our constant desire to meet the growing demands of our customers for reliability, protection, and efficiency. Below is an overview of some of the most notable examples.

Tournaire has repeatedly innovated in terms of product-packaging design to meet specific client needs. In the 2000s, for a customer in the highly demanding anesthesia market, we redesigned the neck geometry of our canisters to improve sealing. The gas contained in our packaging is a volatile anesthetic agent which, at low concentrations in ambient air, can have undesirable physiological effects (drowsiness, headaches, neurological issues…). Moreover, a poorly sealed package could compromise dosage accuracy. The sealing must be absolutely airtight throughout the product’s entire lifecycle and use. Tournaire has successfully supplied this market for over 20 years. This tailored solution is a testament to our ability to meet the most demanding technical challenges while ensuring the reliability required in the healthcare industry.

Another example of product innovation came in 2015, when a major European group and key player in the solvents market approached us to replace their glass packaging with aluminum. The stakes were high: reducing weight, mitigating the risk of breakage, and complying with strict hazardous goods transportation regulations. The challenge was significant: we had to develop a technical solution that was robust, reliable, and economically viable. The first attempts—including the initial Proof of Concept—were unsuccessful. But thanks to our determination, commitment, and collaborative spirit, we overcame the obstacles. After several iterations, we succeeded in developing a solution that met all technical and regulatory constraints—while also improving the user experience. This project remains a strong example of successful collaboration and innovation in the service of industrial and economic performance.

Another case of product innovation emerged in the 2020s, when a customer from the fine chemicals sector reported a critical issue: leaks detected on 3,000 aluminum canisters. The investigation was complex and required a rapid response. During a site visit, our team performed an in-depth analysis of the necks made of plastic and tinplate, taking into account differences in design and materials. We then developed a new closure made of aluminum, specifically adapted to aluminum-based manufacturing processes. This fully redesigned solution permanently resolved the leakage issue. This example illustrates our ability to listen to customers, respond quickly, and deliver tailor-made, innovative, and long-lasting technical solutions.

Packaging professionals know that product innovation cannot exist without industrial innovation. Designing new metallurgical processes tailored to our geometric needs has always been a key part of Tournaire’s innovation journey. On several occasions, we have developed proprietary processes to shape our aluminum packaging:

-

Specific deep drawing: This allows us to optimize the geometry of the canister body by locally adjusting thicknesses and the metallurgical states of the material to perfectly match the expected function. This know-how is the result of deep expertise in metal forming and design.

-

Spinning without mandrel: In this process, the material is spun into a void. Since our canisters are seamless, forming the cone for large diameters (≥120 mm) is a real technical challenge. Aluminum is unpredictable—it flows where it wants. To control its dispersion, Tournaire developed an exclusive and confidential forming tool. A well-kept secret!

Other industrial innovations have also strengthened our production system. Our in-house designed washing machines guarantee a very high level of cleanliness—particulate, microbiological, and hydrocarbon-free. These are developed entirely by our in-house engineering team. Another iconic example: our neck finishing machines, which can perform up to 16 successive operations to achieve an exceptional level of precision.

Over nearly 100 years, all our packaging manufacturing processes have been deeply modernized. By 2025, Tournaire operates more than 18 industrial processes, mainly metallurgical, but also including plastic injection and chemistry for washing systems. All are aligned with process innovations and require specialized tools and/or machines developed specifically for Tournaire. Industrial innovation is a deep-rooted culture, a strategic driver, and a daily commitment to quality, performance, and excellence.

When our product development department collaborates with our lab, the goal goes far beyond simply validating compliance. What we seek above all is to explore the limits of a product. This approach allows us to understand how every technical choice affects overall performance. We are fully engaged in a proactive innovation process. Every detail matters: shape, thickness, metallurgical condition, or the configuration of the aluminum canister components—all have a direct impact on sealing performance. Thanks to our integrated lab and over twenty years of testing data, we have a solid foundation to keep pushing the boundaries of performance.

And when others try to copy us, the results merely reflect the quality of the imitation. Always imitated, never equaled!

In other words, where innovation seeks to create, improve, and offer new solutions, counterfeiting merely copies—without thinking, without understanding, and without creating value. It’s a short-term approach that destroys trust, quality, and integrity. While innovation drives progress, competitiveness, and the visibility of companies, counterfeiting holds back collective momentum, damages the economy, deceives consumers, and weakens the protection of intellectual property rights. That is why Tournaire has always refused to copy and always will—out of respect for others’ work, and in fidelity to our own values of excellence, responsibility, and transparency.

In conclusion, Tournaire embraces a true engineering philosophy that has been part of our DNA since the journey began in 1833. What’s more, our teams love challenges—they stimulate us, motivate us, and give our work meaning. One quote from Mark Twain fits us perfectly: “They didn’t know it was impossible, so they did it.” Creating the canister of the future, developing the industrial means to manufacture it, or bringing an idea to life that simplifies our clients’ operations—these have always been galvanizing and unifying goals. It was in this inspiring context that OMNI+® was born: a 100% recyclable, eco-designed canister—a landmark project that addresses all the needs of today’s and tomorrow’s clients, fully aligned with climate challenges!

The OMNI+® Range: An Innovative Response to Modern Protection and Sustainability Needs

Paired with an innovative industrial tool, the new OMNI+® range is a breakthrough solution that redefines packaging cleanliness.

What truly sets this new generation of closure apart is its eco-design: a solution created to be fully recyclable. The plastic tamper-evident ring can be separated from the rest of the aluminum packaging without the use of any tools. This means the container—composed entirely of aluminum—can be recycled separately from the plastic component. The technical innovations in this range are designed to support the circular economy while reducing the quantity of materials used.

In the case of aluminum, this approach is particularly efficient, as the metal can be infinitely recycled without losing its properties. Companies are investing in the recovery, cleaning, and reuse of packaging while ensuring that this second life does not compromise quality or safety. This approach protects both the product and the planet.

We have also reworked the cap’s ergonomics, particularly the tamper-evident tab, as well as the overall design.

Introduced in the 1980s, the SYSTEM PLUS® closure offered outstanding sealing performance, fully compliant with the strict requirements of ADR regulations (for the transport of hazardous materials).

These results were largely achieved through the crimping of a plastic sleeve, which provided crucial structural rigidity to reduce deformation during drop testing. The standard test involves a fall from 1.8 meters onto a perfectly rigid steel plate, with a simulated load of 98% water, dropped at a specific angle. This setup ensures optimal protection under so-called extreme conditions.

Without a sleeve, it became necessary to find alternative solutions to compensate for the loss of rigidity—and that’s where Tournaire had to innovate. OMNI+® was born.

The phrase “What gets measured gets managed”, attributed to Peter Drucker, aptly captures the importance of measurement in managing and improving performance.

At Tournaire, we evaluate our sustainable performance rigorously. In 2025, we have completed three Carbon Footprint assessments (2022, 2023, 2024), as well as a Life Cycle Assessment (LCA) on eight products in 2024. A new LCA was launched in early 2025, covering other products from our own range and also competitor products for benchmarking.

Simultaneously, we are developing our own in-house tool to calculate the carbon footprint of our products. So when we say the OMNI+® range helps reduce our clients’ environmental impact, it’s a fact—we have the data to back it up. It is available to our clients upon request.

The OMNI+® closure is part of a Product Innovation Roadmap established in 2023.

This roadmap allows us to plan and visualize key stages in the development of new solutions. It aligns strategy, goals, and resources across teams. It helps us anticipate market needs, improve cross-disciplinary collaboration, and make informed decisions for efficient innovation.

To support innovation within the OMNI+® range, we conduct interdisciplinary research.

We have initiated co-eco-design partnerships with select suppliers to collaborate on joint projects. Additionally, we carry out shared initiatives with national organizations such as CEA Tech, IPC, and CETIM.

We are also actively working with CEMEF in Sophia Antipolis, one of the research laboratories of the École des Mines de Paris. Moreover, we have launched a digital twin project—an exact virtual replica of a product—which will help us optimize development timelines. It enables simulation and scenario analysis, facilitating better decision-making at every key project stage.

In conclusion, the OMNI+® range perfectly reflects our commitment to developing solutions that are innovative, high-performance, and sustainable.

While collaboration with research centers and industrial partners is essential, it will never replace the value of dialogue with our clients. Together, we will build the next generation of solutions tailored to real-world needs.

We invite our clients to share their expectations, ideas, and challenges so that we can continue to move forward together. Tournaire will always remain attentive to co-developing the packaging solutions of the future.

CONCLUSION

Technical innovation can be broken down into several categories:

-

Product innovation: It involves creating a new good or service, or improving an existing one, to meet a specific market need.

-

Industrial innovation: It focuses on improving manufacturing methods or industrial processes.

-

Organizational innovation: It concerns how employees are managed and how work is structured and organized.

-

Eco-innovation: It aims not only to protect what matters—our environment—but to do so with efficiency, responsibility, and performance.

At Tournaire, all these types of innovation are considered to meet the needs of all stakeholders involved in packaging, and to ensure a sustainable future for generations to come.

Innovation is the core engine of our global strategy.

Moreover, we clearly see how protection can no longer be left to chance. It is the result of collective effort, in-depth know-how, and the ability to anticipate constraints—such as new regulations—before they even appear. Technical innovation is the tool that turns ambition into concrete solutions.

When it comes to packaging sensitive or hazardous materials, innovation is what ensures the safety of volatile or valuable substances, compliance with strict health standards, optimization of supply chains, and alignment with the increasing expectations for sustainable development.

Ultimately, innovation doesn’t just change the way we manufacture packaging—it changes the way we think about product protection.

It makes it smarter, more coherent, and better suited to today’s world. In a future where products will become increasingly specialized, customized, and regulated, the ability to innovate in packaging will make all the difference.

That’s why, in the industrial packaging sector, innovation is much more than a need: it is a necessity, a promise, and a silent revolution in the service of quality.

This innovation is part of who we are.

The history of Tournaire is, above all, a human journey—one that will celebrate its 200th anniversary in 2033.

It is the story of challenges met by passionate men and women driven by a spirit of innovation; of partnerships and encounters with engaged clients and collaborators; of unique experiences shared across many countries around the world.

We are proud to continue writing this story—together.

Whether in eco-design, responsible innovation, or eco-innovation, Tournaire has a single ambition: to design packaging that reduces environmental impact throughout its life cycle, while guaranteeing our clients high-performance, top-quality solutions.

Want to Know More? Contact the Tournaire Experts

Our guide has given you an overview of the latest developments in PFAS regulations as well as Tournaire’s excellence in providing safe and innovative packaging solutions. If you would like to explore in more detail how our products and services can meet your specific needs, we are here to help.

Our experts are available for personalized consultations.

Visit our contact form to share your needs and questions with us. A member of our team will respond as quickly as possible to provide you with expert advice tailored to your industrial context. Tournaire is committed to providing not only high-quality products but also support and expertise that make a difference. Contact us today to move your project forward with a partner you can rely on.