Discover the news of the industrial group expert in the protection of sensitive and hazardous materials, as well as the list of trade shows and events in which Tournaire participates.

Recycling? It’s as old as the world!

9000 BC… it was around then, apparently, that men first smelted copper, when they realized that it was far easier to melt down and reshape a broken tool than to process the ore necessary to make a new one.

The recycling of basic materials – metals, ferrous or otherwise, plastics, card, glass, etc. – is a widely recognized activity that generates local jobs that cannot be relocated: according to FEDEREC[1], the French Federation of Recycling Companies, French companies in the recycling sector employed 26,000 people at the end of 2013 – over 20% more than in 1999 – in 2,300 companies with total sales of almost 9.5 billion euros.

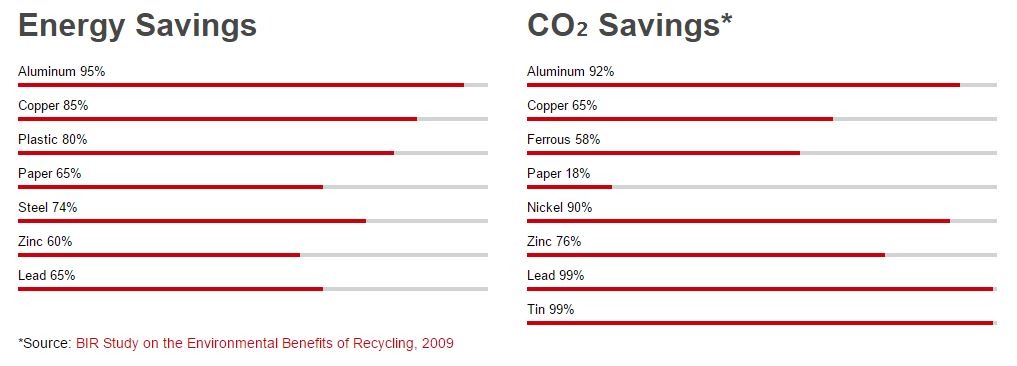

Recycling fits perfectly with the logic of sustainable development: it reduces greenhouse gas emissions, lowers energy consumption, optimizes use of limited natural resources, and avoids the burying of waste in landfill sites. Recycled metals offer advantages in terms of the environment compared to the mining of virgin raw materials, since metals suffer no degradation during the recycling process: they can be infinitely recycled.

Among recycled metals aluminum is without any doubt the one that enables the greatest savings to be made in CO2 emissions and energy consumption, as reported by the web site of the Canadian Association of Recycling Industries, CARI [2].

Perfectly in line with this logic of recycling and value recovery, Tournaire Group’s Packaging Division[3] has for many years produced recyclable products, in compliance with European regulations on packaging design.

Particular attention is thus paid to:

- The extraction and production of raw materials, the transport and packaging of materials delivered to Tournaire;

the manufacture of containers, the recycling of by-products and waste generated by the manufacturing process, and the packaging of the finished product for delivery to the client;

- The end-of-life of containers (recycling of the aluminum and plastic, incineration of plastic accessories).

Finally, its Environmental Management system enables Tournaire, through its Equipment and Packaging Divisions, to achieve continuing progress in limiting its environmental impact.

- All employees are involved in waste sorting, enabling waste to be sent to specialized centers for recovery of materials or energy;

- Effluents are managed on site in Grasse thanks to Tournaire’s own waste water treatment plant;

- Emissions are checked and monitored to ensure that regulatory limits are observed;

- Manufacturing processes are optimized to limit impact on resources (water, gas, electricity);

- Significant means are devoted to monitoring and anticipating regulatory changes so as to ensure that products and equipment comply with the ever-stricter European and French regulations ;

- The company takes part voluntarily in local initiatives in favor of the environment, particularly in the framework of an inter-company Transport Plan.

[3] Tournaire Group’s Packaging Division is certified ISO 14001, as is the Equipment Division