For complete opening, greater ease of use and more reliability for solid and viscous products.

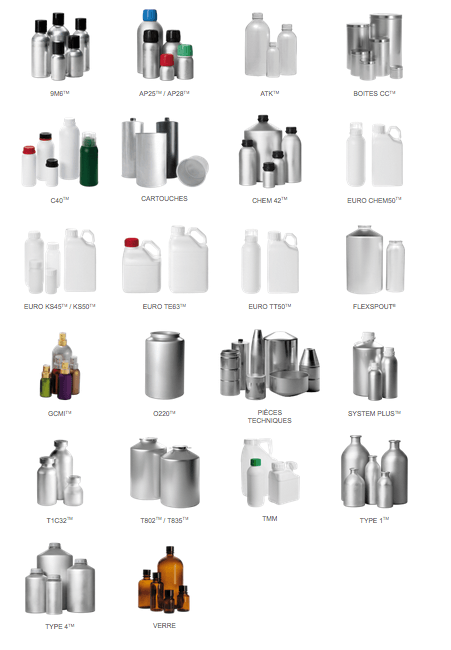

Tournaire’s range of one-piece aluminum containers is already one of the most extensive on the market. However, to meet the constantly evolving demands of its clients Tournaire identified a significant need: bottles with wide openings.

To respond to this need, expressed more and more frequently by clients in markets as diversified as flavors and fragrances, health, fine chemistry, metallic powders or laboratory solvents, Tournaire’s Packaging Division has pushed innovation still further by offering a full range of technical packaging with an extra-wide, 220 mm, opening. This is the O220 range.

Formerly limited to the market for active pharmaceutical ingredients in powder form, the O220 range is now widely used in the other markets supplied by Tournaire, particularly through its international network of distributors and agents. In 2019 Tournaire’s clients have access to this innovation throughout the world, from the Americas to Asia by way of Oceania and Africa.

The O220 range covers capacities from 2.5L to 30L with containers composed of a 220 mm or 300 mm body in one-piece aluminum that is 99.5% pure or better. The body is capped by an aluminum cover in the same grade of metal and a seal in nitrile or silicon, depending on the characteristics of the client’s product. This sealed cap is held in place by a collar, ensuring a perfectly hermetic joint. All these components can be sterilized before filling.

Like the rest of Tournaire’s ranges, the O220 benefits from a very highly level of chemical, microbiological and particulate cleanliness. This absence of contamination is an undoubted asset for applications in the pharmaceutical industry. This level of cleanliness also makes this range ideal for primary packaging and transportation of liquid crystals or fine chemistry products requiring drastic elimination of contaminants.

Since 2019 the O220 range has earned its place in the market for raw materials for the perfume industry. This type of application for the storage, transportation and use of aromatics and perfume materials in powder, solid or viscous form links the O220 to Tournaire’s historic markets and its origins in Grasse.

From ergonomics to safety

The O220 range is equipped with a complete closure system comprising three elements. A standard nitrile seal ensures perfect leakproof qualities, protecting the most sensitive products against external aggression and preventing the release of hazardous substances into the environment. This nitrile seal can be replaced by silicon to make the range compatible with a wide array of other materials. The silicon seal is housed in a cap made of 1050A aluminum (Al 99.5), the same material as the rest of the container, ensuring that the packaged products are in contact with only one type of metal. Once closed the cap is held in place by a collar tightened by a lever system to ensure that the seal is in perfect contact with the lip of the bottle. The cap presses down on the seal and perfect leaktight closure is guaranteed. The collar can be equipped with a lead seal showing that the packaging has not been tampered with. The O220 closure system thus offers high resistance and leakproof qualities even when subject to severe pressure differences, as encountered during air transport for example. By using this range clients can be certain that no residue will remain in the packaging, a positive point both in terms of environmental protection and economic efficiency. The O220 closure system is one of the most effective in the Tournaire range as regards its leaktightness, offering extra safety for the packaging of the most sensitive products.

The excellent performance of the closure system and the technical qualities of the range in no way detract from ease of use since close attention has also been paid to ergonomics. Thanks to the 220mm neck of this range emptying the bottles is easy as the user’s hand and arm can be inserted to ensure that even viscous products can be removed from the bottom of the container.

Tournaire has designed the O220 so that as well as being easy to use it can easily be cleaned by clients and sterilized in several different ways. Also the container can be reclosed between each use with no effect on product conservation.

Available in all markets, throughout the world

This product range is now stocked by most distributors belonging to Tournaire’s international network for various uses everywhere in the world. The O220 range represents an addition to the variety of products with wide openings already proposed by Tournaire: the + 62 system, the Type 4S and the CC container for smaller capacities. Tournaire remains attentive to the needs of its clients and the O220 range is a further item in the long list of relevant solutions perfectly adapted to the wide-ranging needs of our clients throughout the world.

Laurent Carcassonne

Sales and marketing director